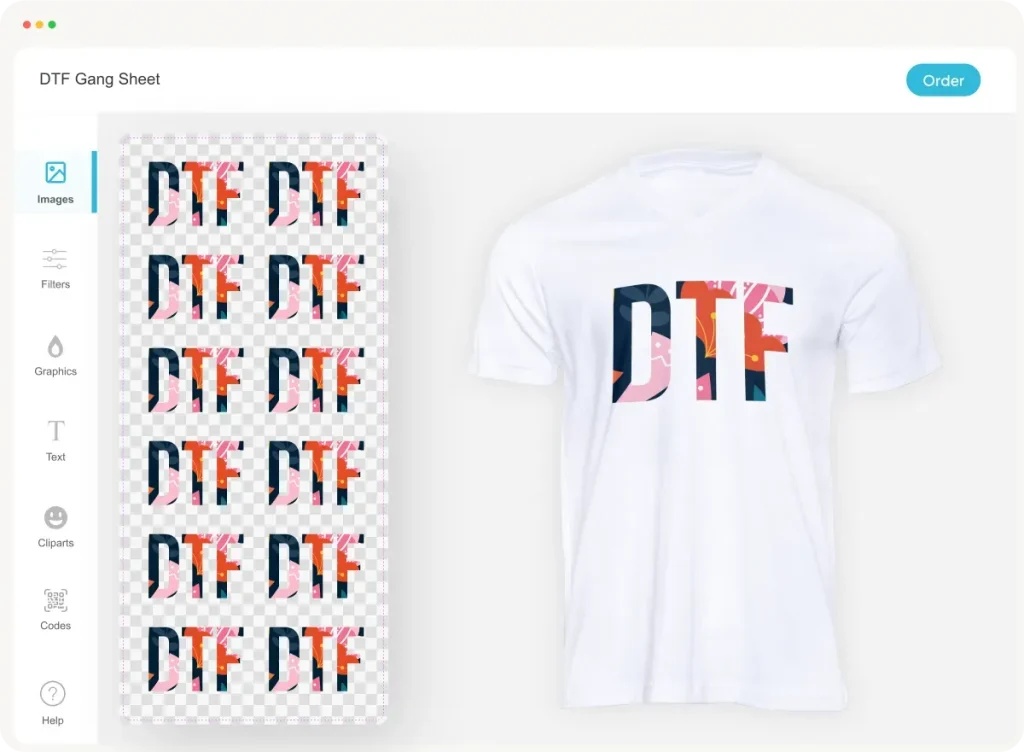

The DTF Gangsheet Builder is transforming the landscape of custom apparel printing for enthusiasts and beginners alike. As a pivotal tool in the Direct-to-Film (DTF) printing process, it allows users to create vibrant designs with incredible efficiency. By mastering gang sheet techniques, you can optimize material usage while reducing waste, enabling a cost-effective approach to printing. Whether you’re just starting or looking to enhance your skills, this guide will provide essential tips and insights into DTF transfer techniques that elevate your print game. Dive into the world of DTF printing with confidence, and discover how the DTF Gangsheet Builder can revolutionize your custom apparel projects.

In the realm of custom garment creation, the Direct-to-Film gang sheet generator serves as a crucial resource for those new to the art of printing. This innovative method allows for versatile designs to be transferred onto fabric through efficient direct-to-film applications. By understanding the principles of DTF printing, aspiring designers can utilize practical tips for constructing their gang sheets, ultimately maximizing material effectiveness and minimizing waste. These techniques not only enhance the quality of prints but also streamline the production process, proving invaluable for professionals and hobbyists engaged in custom clothing manufacturing. Embracing the direct-to-film approach opens doors to endless creative possibilities in apparel design.

What is DTF Printing and How Does It Work?

Direct-to-Film (DTF) printing is a revolutionary method that has transformed the landscape of custom apparel printing. This process involves printing designs onto a special film coated with an adhesive, which is then transferred to various fabrics using heat and pressure. Unlike traditional printing methods such as screen printing, DTF printing allows for intricate designs, vivid colors, and greater flexibility in textile choice. It has rapidly gained popularity due to its ability to produce high-quality graphics that withstand washing and wear, making it ideal for fashion, events, and promotional items.

The basic workflow of DTF printing begins with creating a digital design that is printed onto the film using a DTF printer, which is highly specialized for this purpose. Once printed, the film is coated with a hot-melt powder, which is then heated to bond the ink with the film. After this, the design is placed onto the garment and pressed using a heat press. This method allows for efficient, high-quality prints, which are important for businesses looking to establish a strong brand presence through custom apparel.

Essential Tips for Beginners in DTF Printing

For beginners in DTF printing, mastering the process can initially be overwhelming. However, there are essential tips that simplify this journey. First and foremost, acquiring high-quality DTF inks and films is crucial for obtaining vibrant and long-lasting prints. Utilizing professional design software such as Adobe Illustrator or CorelDRAW can greatly enhance the layout and optimization of gang sheets. Maintaining a systematic approach to designing and organizing your prints can prevent common pitfalls like color mismatches and layout errors.

Additionally, investing time in learning color management is vital. Understanding how to work with CMYK color profiles can ensure that the colors you see on your screen match those that appear on the fabric. Collaborating with other DTF printing enthusiasts through forums or workshops can provide invaluable insights and troubleshooting support, enabling beginners to avoid common mistakes and enhance their learning curve.

Creating Effective DTF Gang Sheets

Creating gang sheets is one of the most efficient strategies for maximizing the use of materials in DTF printing. A gang sheet is a layout that combines multiple designs printed on a single film, which not only saves on material costs but also speeds up the production process. By organizing designs logically and ensuring adequate spacing—typically 1 to 2 inches between each design—printers can maintain design integrity and avoid blurriness during the transfer process.

Utilizing design software with grid functions can optimize the arrangement of designs on gang sheets effectively. It is also crucial to conduct test prints on various fabrics to determine optimal settings; this ensures that the film adheres well and that designs come out crisp and clear, resulting in a professional-grade custom apparel product. This approach not only limits waste but also boosts productivity for those just starting in this vibrant field.

Color Management Strategies for DTF Printing

Color management is a critical aspect of the DTF printing process, especially for those new to the technique. To ensure colors are consistent from digital design to the printed garment, it’s essential to utilize the CMYK color model, specifically tailored for printing purposes. This involves calibrating your printer and software to match color profiles accurately, which can significantly reduce discrepancies in shade and vibrancy between the screen and the final product.

Another effective color management strategy is to create and use color swatches based on the inks being used in the DTF printing process. This will serve as a benchmark, allowing you to adjust designs accordingly and ensure that the expected colors are achieved in the final print. Regular testing and adjustments can keep your colors looking bright and consistent, which is vital for building a reputation for quality in the custom apparel market.

Selecting Quality Materials for DTF Printing

Choosing the right materials is crucial in ensuring the quality and longevity of DTF prints. High-quality films designed specifically for DTF printing are essential in producing vibrant designs that adhere well to a variety of fabrics. Inferior films may lead to poor print quality or adhesive issues, which can compromise the final product and customer satisfaction,

Additionally, selecting eco-solvent inks is becoming a preferred choice among manufacturers due to their ability to yield vibrant colors while being more environmentally friendly. These inks can produce sharp and durable prints that stand the test of washing and wearing, thus ensuring a better return on investment for custom apparel printing ventures.

Community and Resources for DTF Printing Enthusiasts

Engaging with the DTF printing community can greatly enhance your knowledge and skills in this innovative printing method. Numerous online forums and social media groups, such as Facebook or Reddit, provide platforms for enthusiasts to share their experiences, techniques, and troubleshoot daily challenges. Connecting with like-minded individuals can offer both inspiration and practical advice, making the learning process less isolating and more effective.

In addition to community interaction, utilizing online resources such as tutorial videos on platforms like YouTube can provide visual learners with step-by-step guidance on DTF printing techniques, including how to create effective gang sheets. Regularly attending webinars or workshops can also keep you updated on industry trends and advancements, ensuring that your DTF printing processes remain cutting-edge and competitive.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it function?

The DTF Gangsheet Builder streamlines the process of creating multiple designs on a single sheet for Direct-to-Film (DTF) printing. It allows users to maximize material usage and minimize waste, making it an efficient tool for custom apparel printing. By organizing designs carefully, this builder enhances production efficiency for beginners in DTF transfer techniques.

What are the benefits of using a DTF Gangsheet for beginners in DTF printing?

Using a DTF Gangsheet allows beginners to efficiently utilize materials by combining multiple designs on one sheet. This method reduces costs per transfer and speeds up the production process, enabling quicker turnaround for custom apparel printing while maintaining high-quality prints.

How do I layout designs for my DTF Gangsheet?

To layout designs for your DTF Gangsheet, use professional design software like Adobe Illustrator. Implement a grid setup for organized spacing and perform test prints to ensure correct arrangement and avoid blurring during heat transfer. Proper sizing and spacing of 1-2 inches between designs are critical for quality DTF printing.

What materials should I choose for effective DTF printing with gang sheets?

For effective DTF printing, select high-grade films specifically designed for DTF processes and use eco-solvent inks to achieve vibrant results. The quality of the materials directly impacts the overall success of your prints, making these choices crucial in the DTF Gangsheet Builder process.

How can I improve color accuracy when using a DTF Gangsheet?

To improve color accuracy in your DTF Gangsheet designs, utilize CMYK color profiles and color swatches from your DTF ink manufacturer. This practice helps maintain consistency between your digital designs and the final printed results, ensuring vibrant and true-to-color transfers.

What troubleshooting resources are available for DTF Gangsheet printing challenges?

Troubleshooting resources for DTF Gangsheet printing include online forums, community support groups on social media, and tutorial videos on platforms like YouTube. Engaging with these resources can provide solutions for common challenges faced during direct-to-film printing and enhance your skill in building effective gang sheets.

| Key Point | Details |

|---|---|

| Understanding DTF Printing | DTF printing transfers designs onto fabrics using a specialized film, achieving vibrant and long-lasting results. |

| Importance of DTF Gangsheet | Gang sheets maximize material usage, minimize waste, and enable efficient production through batch printing. |

| Key Tips for Building DTF Gangsheet | 1. Use design software for optimal layout. 2. Manage colors with CMYK profiles. 3. Ensure proper spacing (1-2 inches between designs). 4. Choose high-quality films and eco-solvent inks. 5. Conduct test prints on various fabrics. |

| Maintenance and Resources | Regular printer maintenance is crucial. Engage with online forums and watch tutorials for learning and troubleshooting. |

Summary

The DTF Gangsheet Builder is an innovative tool that transforms your custom apparel printing experience. By mastering the techniques outlined in this guide, you can unlock the full potential of DTF printing, making it a highly efficient and cost-effective solution for creating vibrant, long-lasting designs on fabric. As you delve into the world of DTF printing, remember the importance of optimizing material usage and investing time in learning about software and color management. With dedication and the right resources, the DTF Gangsheet Builder will not only enhance your printing capabilities but also help you create stunning apparel that stands out in the marketplace.