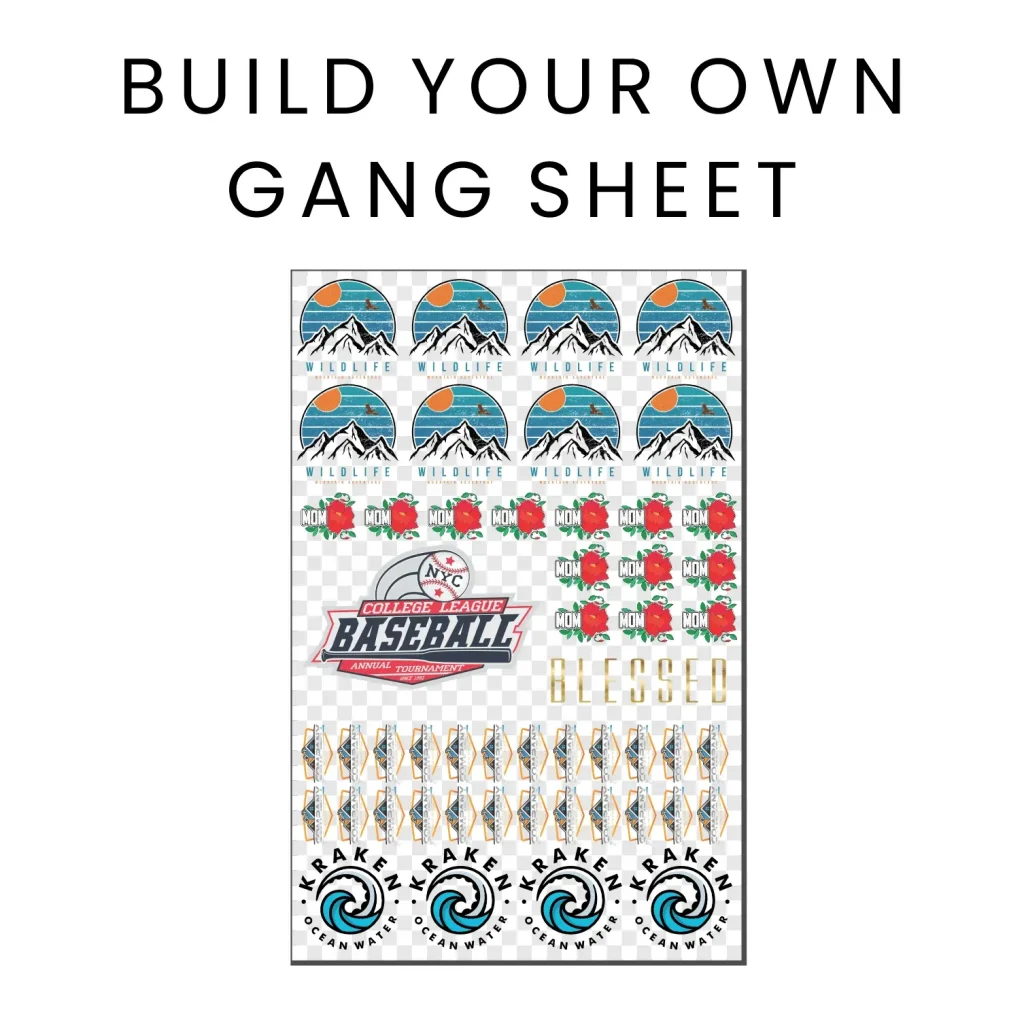

The DTF gangsheets builder is a groundbreaking tool that has redefined the landscape of Direct-to-Film (DTF) printing, making it more accessible and efficient for graphic designers and small businesses alike. This innovative technology enables users to create multiple designs on a single sheet of film, dramatically streamlining the printing process. By mastering the DTF gangsheets builder, you can optimize gangsheet layouts to enhance your overall output quality while efficiently minimizing material waste. This guide will walk you through everything from DTF technology fundamentals to essential heat press tips, ensuring you can leverage graphic design for DTF printing like a pro. Join us as we delve into the exciting world of DTF printing and explore how you can elevate your craft with the right tools and techniques.

The DTF gangsheets builder is essentially an advanced design tool for Direct-to-Film printing, facilitating the creation of intricate gangsheet layouts that optimize film usage. This technology empowers creatives to piece together various designs on a single film sheet, enhancing efficiency in the printing process. Additionally, understanding the nuances of DTF printing technology—such as how to properly use heat press equipment and the importance of graphic design principles—can greatly influence the final product quality. With strategic planning and an eye for design, anyone can harness the potential of this versatile tool, making it a vital asset in the textile printing industry. Whether you’re a seasoned professional or a newcomer, grasping these concepts is key to unlocking your full DTF printing potential.

Understanding the Fundamentals of DTF Technology

To effectively utilize DTF printing, it’s crucial to grasp the fundamental concepts behind DTF technology. At its core, DTF (Direct-to-Film) printing involves printing designs onto a special film that can then be transferred to fabric using a heat press. This method has gained popularity for its ability to produce vivid colors and detailed graphics that stand the test of time. DTF technology not only simplifies the print process but also minimizes the risk of color blending that can occur in traditional printing methods. By employing DTF gangsheets, users can print multiple designs simultaneously, optimizing workflow and significantly cutting down production costs.

The beauty of DTF technology lies in its versatility, allowing for both small batch runs and large-scale production. Unlike traditional methods that require different types of inks and materials for different fabrics, DTF printing works seamlessly across various fabric types, including cotton, polyester, and blends. This adaptability makes it an attractive option for graphic designers looking to expand their offerings and for businesses aiming to provide customized apparel quickly and efficiently. By mastering the DTF gangsheet builder, you open the door to endless creative possibilities in textile printing.

Essential Setup Steps for DTF Gangsheet Builder

Setting up your equipment correctly is the first step to mastering the DTF gangsheet builder. This involves properly configuring your DTF printer and heat press to ensure that every print meets high-quality standards. Begin by calibrating your printer according to the manufacturer’s guidelines to achieve accurate color reproduction. Neglecting the calibration process can lead to inconsistent prints and improper colors, affecting the overall appeal of your final product. Additionally, it’s essential to adjust the temperature settings on your heat press, as this directly influences the effectiveness of transfer adhesive in bonding designs to fabrics.

Another integral part of the setup process is regular maintenance of your equipment. Cleaning the DTF printer heads routinely can prevent ink clogging, which can severely impact print quality. It’s advisable to create a maintenance schedule to stay on top of cleaning and servicing your devices. When your printers and heat presses are in excellent condition, the chances of achieving successful prints on your DTF gangsheets increase significantly. This not only boosts productivity but also enhances the longevity of your equipment, ensuring a reliable printing operation for your business.

Choosing the Right Software for DTF Printing

Selecting the right software is a critical component when using your DTF gangsheet builder effectively. Specialized software platforms help streamline the printing process, with Raster Image Processor (RIP) software being particularly beneficial for DTF printing. Such software optimizes designs for printing by facilitating white ink management, ensuring vibrant and true-to-color prints, especially on darker fabrics. Moreover, features for layout flexibility allow users to arrange multiple designs on a gangsheets efficiently, maximizing the use of film and minimizing waste.

Additionally, it’s important to ensure that the software you choose is compatible with your DTF printer. Compatibility ensures that you can take full advantage of all the software’s functionalities, significantly improving your printing workflow. Investing in good graphics software also means that you can access tools for optimizing your designs right at the start. With the right software solutions in place, printing becomes more manageable, allowing for a smoother process from design creation to the final product.

Creative Design Tips for DTF Gangsheet Layouts

When designing for your DTF gangsheet, there are essential design tips to keep in mind for optimal results. Working with high-resolution images is crucial; designs should ideally be at least 300 DPI to ensure sharp and clear outputs during the printing process. Using vector files is also ideal, as they retain quality regardless of size adjustments. Furthermore, consider the arrangement of multiple designs on your gangsheets thoughtfully; by strategically placing designs, you can enhance space utilization and decrease material wastage.

Utilizing design software like Adobe Illustrator or CorelDRAW can significantly enhance your graphic design capabilities for DTF printing. These platforms offer advanced tools for creating intricate graphics that can then be arranged compellingly on the gangsheets. Additionally, incorporating a variety of design elements—such as textures, patterns, and colors—can elevate your print quality and make your products stand out in a competitive market. Remember, the layout not only affects aesthetics but also the efficiency of the printing process.

Mastering the DTF Printing Process

Once your designs are finalized, it’s time to delve into the DTF printing process itself. Begin by importing your design files into the DTF printer through your chosen software, ensuring that the correct settings for ink and film type are selected. This step is critical; improper configurations can lead to subpar prints that fail to meet quality expectations. Regular monitoring of the printing process is equally essential, as keeping the printer heads clean and well-maintained prevents common printing issues that could jeopardize your output.

During printing, remaining vigilant allows you to catch any potential problems early. Regular checks can help identify issues like misalignment or color discrepancies which are easily rectified if caught in time. Adopting a proactive approach during the printing phase not only assures better product quality but also contributes to a more efficient workflow. The more optimized your printing process, the quicker you can produce and deliver high-quality products to your customers.

Applying Completed Transfers Accurately

After the printing stage, applying your DTF transfers onto the chosen fabric is the next critical step. Properly applying adhesive is essential; an even sprinkle of powdered adhesive over the printed designs ensures a robust bond between the print and the fabric. Taking the time to evenly distribute the adhesive can significantly influence the durability of the final product, preventing issues like peeling or cracking after washing. This step should not be rushed, as it lays the groundwork for the success of your DTF printing endeavors.

Following adhesive application, using a heat press is imperative to cure the transfers effectively. Adhering strictly to the recommended temperature and time guidelines is critical for optimal adhesion and long-lasting results. Insufficient heat or time can lead to inadequate curing, resulting in a print that may come off easily with washing. By following these detailed heat press tips, you can guarantee that your finished products are not only visually appealing but also durable enough to withstand daily usage, enhancing customer satisfaction.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it enhance DTF printing?

A DTF gangsheet builder is a specialized tool used in DTF printing that allows you to arrange multiple designs on a single sheet of transfer film. This enhances efficiency by maximizing material usage and reducing waste during the printing process, ultimately lowering production costs while maintaining high-quality output.

What software is best for optimizing designs in a DTF gangsheet builder?

For effective use of a DTF gangsheet builder, specialized software such as Raster Image Processor (RIP) is recommended. This software helps in white ink management, maximizing layout flexibility, and ensuring that your designs are printed with optimal color vibrancy and accuracy.

What tips should I follow for a successful heat press application in DTF printing?

When using a heat press with your DTF gangsheets, ensure that you follow the correct time and temperature settings as recommended by the film manufacturer. Additionally, it’s important to use an even application of adhesive on your printed designs before pressing, as this will ensure a strong bond and enhance durability.

How can I ensure my designs are high-quality for printing with a DTF gangsheet builder?

To achieve high-quality prints with a DTF gangsheet builder, always work with high-resolution files of at least 300 DPI. This ensures that details in your designs are crisp and clear. Also, strategically arrange designs on your gangsheets to optimize space and reduce film waste.

What regular maintenance should I perform on my DTF printer used with a gangsheet builder?

Regular maintenance for your DTF printer involves cleaning the printer heads to prevent clogging and ensuring proper alignment. Additionally, check the calibration settings frequently to maintain color accuracy, which is crucial for producing vibrant prints on fabric.

How do I perform wash tests to ensure durability of DTF prints?

To conduct wash tests for your DTF prints, wash test garments using different water temperatures and detergents. Monitor color retention and fabric integrity after multiple washes to ensure that your printed designs will hold up over time. This step is essential for validating the quality of your final product.

| Key Areas | Details |

|---|---|

| Understanding DTF Technology | Overview of DTF printing process and benefits of gangsheets for efficiency and cost reduction. |

| Setting Up Your Equipment | Proper configuration of printer and heat press is crucial; regular maintenance prevents issues. |

| Choosing the Right Software | Utilize specialized software for sound printing management, white ink handling, and design layout. |

| Design Creation | Create high-resolution designs and optimize layouts to minimize film waste. |

| Printing Process | Load files with appropriate settings and monitor the printing for quality assurance. |

| Applying Transfers | Apply adhesive and use a heat press following specific guidelines for durability. |

| Testing and Quality Assurance | Conduct test prints and wash tests to ensure quality and longevity of designs. |

Summary

The DTF gangsheets builder is a powerful tool in the textile printing landscape, enabling creators to efficiently produce vibrant and durable designs. Mastering its diverse functionalities not only facilitates a streamlined printing process but also significantly enhances the quality of the final output while minimizing material waste. Understanding the fundamental principles of DTF printing, combined with strategic equipment setup, optimal software use, and meticulous design practices, positions users to achieve remarkable results. Whether you’re just starting or seeking to refine your skills, this guide empowers you to excel in utilizing the DTF gangsheets builder for all your creative endeavors. Embrace this technology with confidence to elevate your printing business today!