The DTF Gangsheet Builder is revolutionizing the textile printing landscape, merging innovation with efficiency to cater to modern business needs. DTF (Direct-to-Film) printing stands out as an advanced printing method that enhances production speed and lowers costs, making it a compelling alternative to traditional printing methods. With its ability to produce vibrant prints on various fabrics, the DTF method is quickly gaining traction due to its exceptional print quality comparison against older techniques. Businesses can leverage the benefits of DTF printing, from reduced setup times to eco-friendly practices that align with growing consumer preferences. As more companies recognize the importance of adopting cutting-edge technologies, the DTF Gangsheet Builder emerges as a pivotal tool for achieving success in the highly competitive textile market.

In the realm of fabric printing, the Direct-to-Film Gangsheet Builder represents a significant shift from conventional methods, offering a modern solution for businesses aiming to improve their production processes. This innovative printing technology allows for high-resolution designs to be transferred onto textiles with remarkable efficiency, outperforming traditional screen printing. By enabling a quick turnaround of unique and custom designs, this approach caters to the rising demand for personalized products. Furthermore, the use of environmentally-friendly materials in DTF printing resonates with the sustainability movement, providing a greener alternative to outdated practices. As the textile industry evolves, the adoption of DTF techniques not only enhances print quality but also equips businesses to meet the intricate demands of today’s consumers.

1. Key Features of DTF Printing Technology

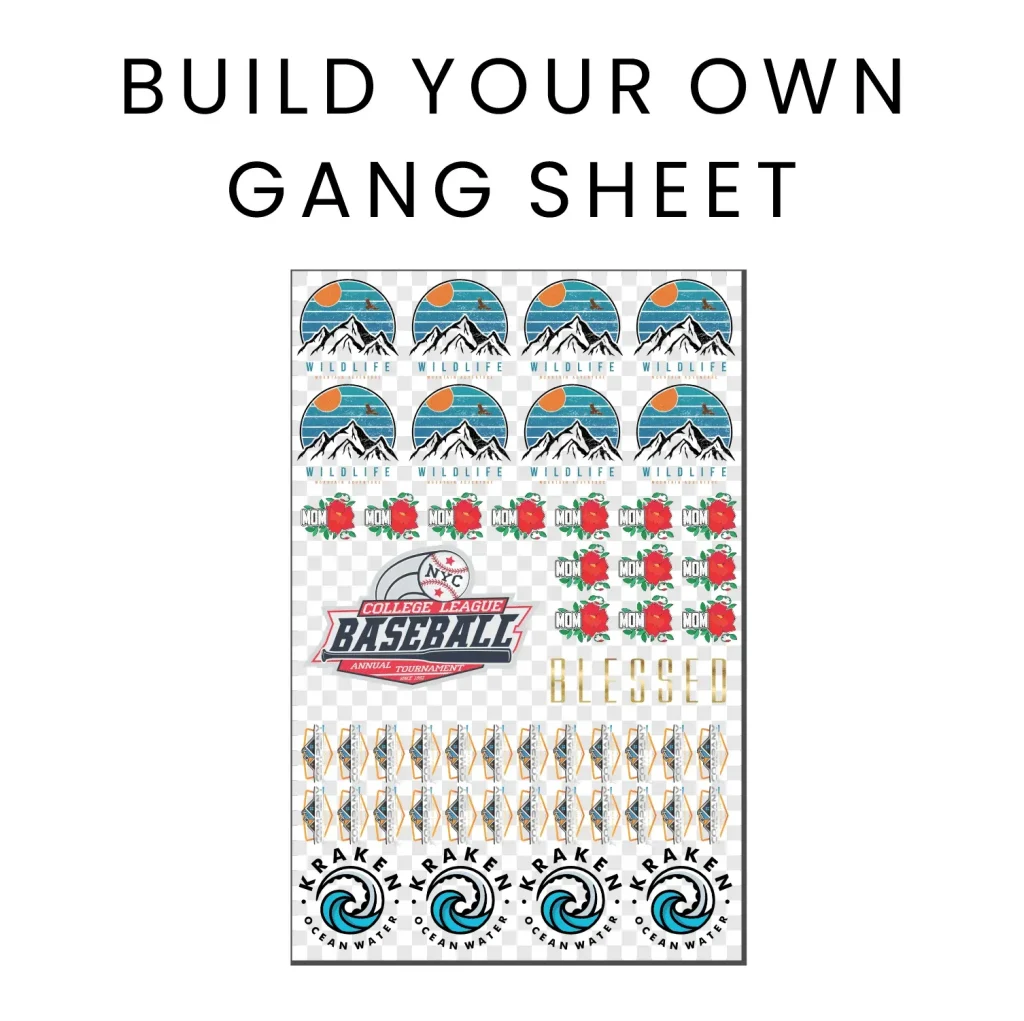

DTF printing technology is revolutionizing the way textiles are printed through its innovative approach. This method utilizes a transfer film that can hold intricate designs and a broad spectrum of vibrant colors, which are then heat-transferred onto the fabric. Unlike traditional printing methods that often rely on numerous screens and setup time, DTF printing streamlines the process by allowing multiple designs to be printed on a single sheet, known as a gang sheet. This not only speeds up the production process but also enhances the overall quality of the print.

Additionally, DTF printing supports various fabric types including cotton, polyester, and blends, making it highly adaptable across different markets. The technology’s versatility permits businesses to meet diverse customer needs without the limitations faced by traditional screen printing methods. This multi-faceted approach not only highlights the capabilities of DTF printing but also its significant advantage in maintaining high-quality standards across various materials.

2. Advantages of Using DTF Gangsheet Builders

One of the most significant advantages of utilizing DTF Gangsheet Builders is their efficiency in managing production runs. By allowing businesses to print multiple designs simultaneously on one sheet, these builders dramatically reduce the time spent on setup and production. Traditional methods can not only be labor-intensive but also require additional resources per design, leading to higher operational costs. As businesses strive for optimized workflows, DTF gang sheets present an advantageous alternative that enhances efficiency without sacrificing quality.

Furthermore, the cost-effectiveness of DTF Gangsheet Builders is evident, particularly for businesses operating in low to medium production scenarios. By eliminating the need for multiple screens and extensive setup processes, companies can cut down on both material and labor costs, leading to higher profit margins. This feature is particularly beneficial for custom print jobs, where customers are increasingly searching for personalization without the corresponding premium charges typical of traditional printing methods.

3. Print Quality Comparison: DTF vs Traditional Methods

When it comes to print quality, DTF printing stands out due to its superior adherence and permanence. Fabric treated with DTF prints exhibits vibrant, enduring colors that withstand washes better than many traditional printing methods. Traditional screen printing often struggles with color fidelity and can result in prints that fade or crack over time. The shift towards DTF technology not only caters to aesthetic demands but also meets the durability expectations of consumers who value longevity in their purchased items.

Moreover, DTF printing allows for finer details in designs, making it a preferred choice for businesses looking to produce high-resolution graphics on fabric. This level of detail is often lost in traditional methods, which can require larger screens for intricate designs. As marketing trends move towards keeping pace with consumer expectations, the print quality differentiation between DTF and traditional printers plays an essential role in capturing customer interest.

4. The Role of DTF in Eco-Friendly Printing

In today’s environmentally conscious marketplace, the push for sustainable printing methods has become a significant consideration for businesses. DTF printing offers a more eco-friendly approach due to its reliance on water-based inks, unlike traditional printing methods that often involve solvent-based inks. Water-based options present fewer environmental risks and health hazards for workers, aligning printing practices with global sustainability goals.

Transitioning to DTF printing can enhance a company’s brand image as a responsible, environmentally aware choice. As consumers increasingly opt for brands that reflect their values regarding sustainability, embracing eco-friendly printing practices can not only help in reducing harmful environmental impacts but also contribute to overall customer loyalty. As a result, businesses that adopt DTF technologies find themselves better positioned in a market that increasingly prioritizes ethical practices.

5. Navigating the Transition to DTF Printing

For businesses considering a switch from traditional printing methods to DTF printing technology, understanding the transition process is crucial. The initial stages may require investment in DTF gangsheet builders and training for operators, but the long-term benefits often outweigh the initial challenges. Companies need to assess their current printing volumes and determine how DTF can fit into their operational model to maximize output and efficiency.

Moreover, communicating the advantages of DTF printing to potential clients can help ease the transition. Highlighting factors like faster turnaround times, lower costs, and superior print quality can win over customers hesitant to embrace new technology. As more businesses share success stories about their DTF printing experiences, the overall industry shift towards this method becomes more apparent, enticing more players to join this innovative approach.

6. Future Trends in DTF Printing Technology

As the DTF printing landscape continues to evolve, experts predict significant advancements that will enhance quality, efficiency, and usability. Future developments may include improved ink formulations that increase vibrancy and durability, further bridging the gap between DTF and traditional printing methods. Furthermore, innovations in DTF gangsheet builders are likely to emphasize automation, enabling even smaller operations to achieve large-scale efficiencies without increasing costs.

Additionally, as consumer demands shift towards more personalized products, DTF printing’s adaptability will likely position it as a leader in the textile printing market. Industry leaders are already spotlighting growth trends indicating that DTF adoption is not just a passing trend but is here to stay. As competition heightens, those investing in DTF technology and keeping up with future advancements will be well-poised to dominate their respective markets.

Frequently Asked Questions

What are the advantages of using the DTF Gangsheet Builder over traditional printing methods?

The DTF Gangsheet Builder offers several advantages over traditional printing methods including enhanced efficiency, cost-effectiveness, and better print quality. By enabling multiple designs to be printed on a single sheet, businesses can significantly reduce production lead times and costs. Additionally, DTF printing produces vibrant, durable prints that are more resilient compared to traditional screen printing techniques.

How does DTF printing compare to traditional methods in terms of print quality?

DTF printing is known for its superior print quality. It produces vivid colors and durable images that resist fading and cracking, making it preferable for a variety of fabrics. In contrast, traditional printing methods may sometimes yield less vibrant results and can struggle with adherence to different materials.

Why should businesses consider the eco-friendly aspects of DTF printing with the Gangsheet Builder?

Businesses should consider DTF printing because it typically uses water-based inks, which are less harmful to the environment compared to the solvent-based inks found in traditional printing methods. As environmental awareness grows among consumers, adopting eco-friendly printing technologies like DTF supports sustainable practices and aligns with market demands.

What makes the DTF Gangsheet Builder user-friendly for newcomers to the printing industry?

The DTF Gangsheet Builder is designed with a user-friendly interface that simplifies the printing process. This allows even inexperienced users to create high-quality prints quickly, without needing extensive training or expertise that traditional screen printing often requires.

Can DTF printing accommodate unique and customized designs better than traditional methods?

Yes, DTF printing is highly versatile and excels at accommodating unique and customized designs. It allows for intricate patterns and a broader color palette, enabling businesses to meet customer demands for personalized products, which can be a limitation in traditional screen printing methods.

How does the DTF Gangsheet Builder improve production efficiency compared to traditional printing methods?

The DTF Gangsheet Builder improves production efficiency by allowing multiple designs to be printed on a single sheet, drastically reducing setup times and labor costs. Traditional printing methods often require separate screens for each design and color, resulting in longer production cycles and potential bottlenecks.

| Aspect | DTF Gangsheet Builder | Traditional Methods |

|---|---|---|

| Efficiency and Speed | Allows multiple designs on one sheet, reduces production lead times. | Requires separate screens for each design, leading to longer setup times. |

| Cost-Effectiveness | Minimizes resources, ideal for small and medium production runs. | High overhead costs due to individualized screens and extensive labor. |

| Versatility in Design | Capable of intricate designs and a wider color palette. | Limited by traditional methods in terms of design complexity. |

| Quality of Print | Produces durable, vibrant images that adhere well to fabrics. | Less vibrant outcomes with risks of fading and peeling. |

| Ease of Use | User-friendly, accessible for newcomers to the industry. | Requires high level of expertise for effective operation. |

| Environmental Considerations | Utilizes water-based inks, more eco-friendly. | Often uses solvent-based inks, less environmentally friendly. |

Summary

The DTF Gangsheet Builder is revolutionizing the textile printing landscape, offering significant advantages over traditional printing methods. By leveraging efficiency, cost-effectiveness, versatility, print quality, ease of use, and environmental consciousness, the DTF method enables businesses to meet customer demands for high-quality, customized products while maximizing production efficiency. As the industry moves toward a more technologically advanced future, adopting the DTF Gangsheet Builder has become essential for companies aiming to thrive and innovate.