In the evolving landscape of textile printing, the **DTF Gangsheet Builder** stands out as a game-changing tool for both amateur and professional designers. By harnessing the power of Direct to Film (DTF) printing, this innovative builder simplifies the process of creating multiple designs on a single film sheet, optimizing production efficiency while maintaining high-quality prints. Cost-effective printing is now within reach for many, as designers can maximize their resources without compromising on creativity. Coupling DTF technology with effective graphic design tips, users can produce vibrant visuals that captivate audiences. Join us as we delve into the features and techniques that make the DTF Gangsheet Builder an indispensable asset for any textile printing endeavor.

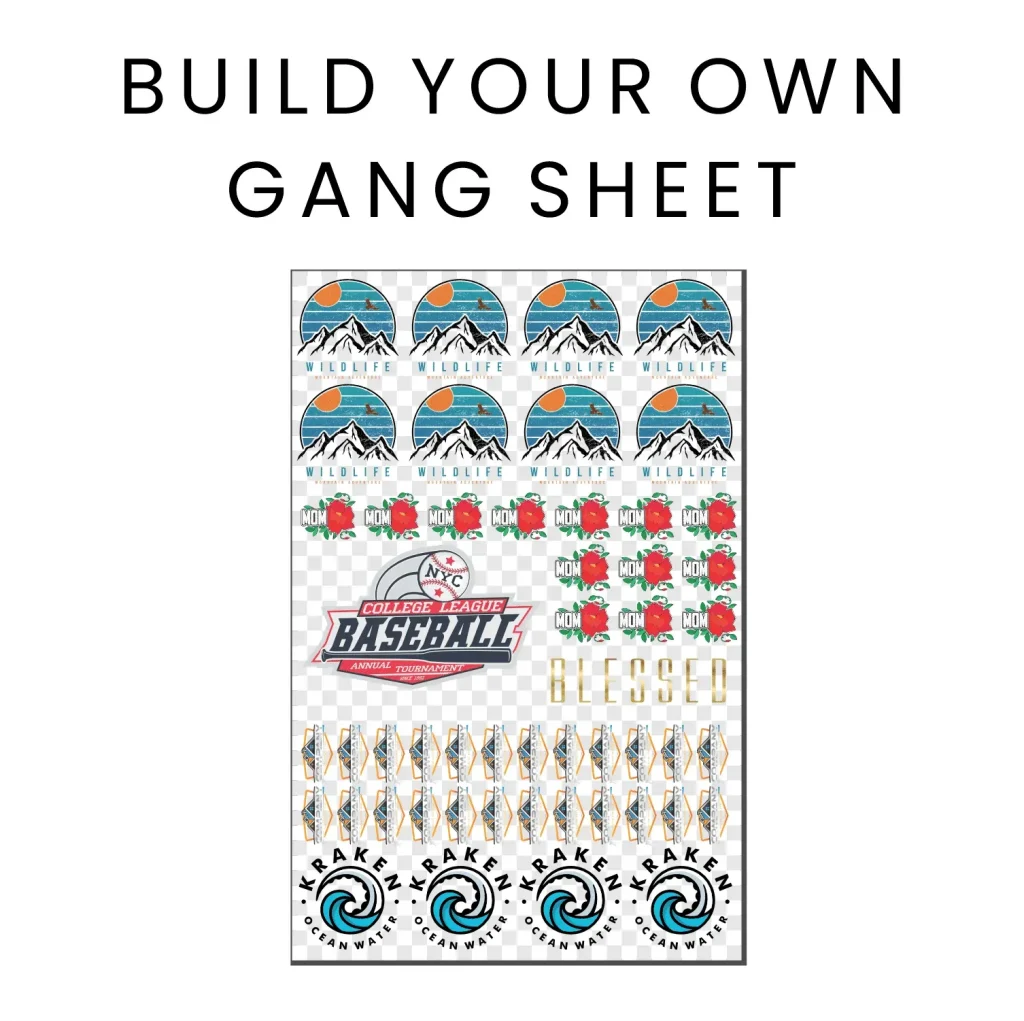

The world of direct-to-garment printing continues to thrive, and at its core lies the revolutionary gangsheet creation tool. Known for its remarkable efficiency, this approach allows designers to consolidate various illustrations onto a single transfer sheet, enhancing both material usage and budget management. As we explore the intricacies of this textile printing technique, we’ll uncover essential strategies and insights, helping you elevate your printing projects. Whether you’re looking for advice on layout optimization or tips for selecting the right materials, this overview will guide you through the essentials of gangsheet printing. Get ready to unlock the full potential of your designs with effective textile printing techniques.

Understanding DTF Printing Technology

Direct to Film (DTF) printing technology has revolutionized the way designers approach textile printing. Unlike conventional methods such as screen printing, DTF allows for direct transfer of vibrant, high-resolution images onto fabrics. This eliminates the need for screen creation, offering a more timely and cost-efficient solution for businesses of all sizes. Due to its capability of delivering full-color designs, DTF has quickly gained popularity among graphic designers and textile printing companies.

In the DTF printing process, a transfer film is utilized to apply inks onto fabrics. This method not only provides flexibility in design but also permits intricate details and gradient colors that are often challenging to achieve with traditional printing techniques. As a result, DTF printing is particularly favored in customized apparel, promotional items, and specialized designs, allowing businesses to cater to unique consumer demands.

Maximizing Efficiency with DTF Gangsheet Builder

The DTF Gangsheet Builder is a crucial tool for anyone involved in DTF printing, designed to improve workflow and reduce production costs. By allowing users to consolidate multiple designs into a single print run, this software significantly reduces waste and maximizes the use of materials. This method of gangsheet printing appeals particularly to small businesses looking to streamline their production processes while maintaining high-quality outcomes.

Moreover, the ease of use of the gangsheet builder makes it accessible for both novices and seasoned professionals. It typically features intuitive layouts and drag-and-drop functions, enabling designers to effortlessly arrange their graphics. Utilizing this software not only boosts productivity but also enhances the overall creative process, empowering designers to focus more on innovation in their textile designs.

Essential Graphic Design Tips for DTF Printing

When working with DTF printing, certain graphic design tips can significantly enhance the final outcomes. First and foremost, designers should always prioritize high-resolution image files. Ensuring clarity and detail in the original graphics leads to sharper prints, and vector images are preferred since they can be scaled without losing quality. This is particularly vital in a competitive market where quality directly impacts customer satisfaction.

Additionally, effective color separation is crucial in DTF printing due to the printer’s efficient handling of a limited color palette. By skillfully separating colors and minimizing the variety used in designs, one can achieve vibrant results without complications during the printing process. These techniques, combined with an understanding of color theory and textile printing techniques, can elevate the success of any DTF project.

Optimizing Your Design Layout

When utilizing the DTF gangsheet builder, optimizing your design layout is key to achieving the best results. Many gangsheet printing tools come equipped with templates that can guide users in organizing their designs effectively. By strategically placing designs to maximize space usage, designers not only reduce material waste but can also enhance the aesthetic impact of their prints. This layout optimization generally leads to a more cohesive final product.

Moreover, understanding the dimensions of your transfer film and how different designs will interact on the sheet will further improve the layout. For instance, combining larger designs with smaller elements can create striking visual hierarchies. As a designer, if you pay attention to these details while using the gangsheet builder, the overall output will be significantly improved, ensuring that each print stands out.

Importance of Test Prints in DTF Printing

Conducting test prints before a full production run is an essential practice in DTF printing. Test prints allow designers to evaluate color accuracy, design placement, and material compatibility without the commitment of a large print run. By using smaller, preliminary prints, one can easily identify potential issues such as color mismatches or graphic blurring, allowing for adjustments that can save time and resources in the long run.

Additionally, these tests provide an invaluable opportunity to experiment with various fabrics and inks. Different materials may react differently with DTF inks, affecting the vibrancy and durability of the final product. Therefore, regular testing not only leads to better print quality but also fosters a deeper understanding of the diverse surfaces that can be printed on, enhancing overall expertise in textile printing techniques.

Staying Connected in the DTF Printing Community

Staying engaged with the DTF printing community is a great way to keep skills sharp and current with industry developments. By following influential blogs and forums, designers can access a wealth of information, from latest trends and techniques to common pitfalls and solutions. Communities like these often provide a platform for asking questions and sharing experiences that can significantly aid in improving one’s own printing process.

Furthermore, engaging with video tutorials on platforms like YouTube can also enhance your learning curve. These resources often showcase practical applications of DTF printing techniques, including how to effectively use gangsheet builders to maximize design potential. Incorporating insights from both written and visual resources allows designers to broaden their knowledge and adapt their methods to stay ahead in a fast-evolving industry.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized tool designed for Direct to Film (DTF) printing that allows designers to create multiple designs on a single film sheet. By optimizing the layout and arrangement of designs, users can minimize material waste and reduce costs while achieving stunning prints.

How can I improve my graphic design for DTF printing using the Gangsheet Builder?

To improve your graphic design for DTF printing with the Gangsheet Builder, use high-resolution images, optimize color separation for a limited palette, and utilize design templates to maximize the efficiency of your layout. Conducting test prints can also help ensure color accuracy and visual impact.

What are the benefits of using gangsheet printing with the DTF Gangsheet Builder?

Gangsheet printing with the DTF Gangsheet Builder offers several benefits, including cost-effectiveness by utilizing fewer materials, streamlined production processes, and the ability to print multiple designs at once, which is ideal for small businesses and freelance designers.

What textile printing techniques should I know when using the DTF Gangsheet Builder?

When using the DTF Gangsheet Builder, it’s important to understand techniques such as color separation, ink type selection, and matching materials for compatibility with DTF printing. This knowledge can significantly improve the quality and durability of your printed designs.

Can I use the DTF Gangsheet Builder with different types of textiles?

Yes, the DTF Gangsheet Builder can be used with various textiles like cotton, polyester, and blends. When selecting materials, ensure they are compatible with DTF printing processes to achieve the best results in terms of color vibrancy and wash durability.

What graphic design tips should I follow for effective DTF printing?

For effective DTF printing, consider these graphic design tips: use high-quality images, limit your color palette for easier management, take advantage of design templates in the DTF Gangsheet Builder, and always conduct test prints to assess your designs before full production.

| Key Points | Details |

|---|---|

| What is DTF Printing? | A printing technology that transfers full-color designs onto garments without screens or stencils, saving time and costs. |

| The DTF Gangsheet Approach | Combines multiple designs into one film sheet to minimize costs and optimize material use. The gangsheet builder helps arrange these designs efficiently. |

| Tips for Effective Design | 1. Use high-resolution images. 2. Effective color separation for vibrant prints. 3. Optimize design layout using templates. 4. Conduct test prints before large runs. 5. Invest in recommended design software. |

| Understanding Ink Types | Plastisol inks are preferred for their vibrant colors and durability. Ensure material compatibility for best results. |

| Staying Updated | Follow industry blogs, engage with online communities, and watch tutorials to keep skills updated. |

Summary

The DTF Gangsheet Builder offers a powerful platform for creating stunning textile designs that stand out in the competitive market. By leveraging the features of this tool and implementing the tips discussed, designers can enhance their workflow, reduce costs, and produce high-quality prints that captivate customers. Emphasizing practices such as using high-resolution images, conducting test prints, and staying informed about DTF trends will further empower creators to excel in their craft. With these strategies, the DTF Gangsheet Builder not only transforms design ideas into vibrant realities but also boosts the efficiency and profitability of textile printing businesses.