The **DTF gangsheets process** is revolutionizing the world of custom apparel printing, offering a sophisticated way to produce multiple designs on a single sheet of film. With the rise of Direct to Film (DTF) printing techniques, printers now have an efficient method for transferring intricate designs onto fabrics, all while minimizing material waste and production time. Within the DTF transfer process, efficiency meets quality, allowing for stunning, vibrant results that elevate any apparel line. This introduction will delve into the steps necessary to master the gangsheets printing method, guiding you to enhance your printing skills. As print professionals navigate this innovative landscape, understanding the DTF process becomes paramount to staying competitive in the textile industry.

Exploring the fascinating realm of **gang sheets printing**, this guide offers insights into an advanced technique that simplifies the process of printing custom designs onto textiles. Also known as Direct to Film (DTF) methods, these approaches harness innovative printing technologies to create high-quality apparel designs efficiently. By learning the nuances of the DTF print technique, individuals in the textile sector can maximize their output while maintaining excellent durability and color integrity. Understanding the gangsheets process is crucial for anyone aiming to enhance their skills in custom fabric printing, paving the way for creative expression and business growth in the vibrant world of fashion.

Understanding the Fundamentals of DTF Printing Techniques

Direct to Film (DTF) printing techniques have gained popularity due to their ability to produce high-quality images with less waste compared to traditional printing methods. This process involves printing designs directly onto a special film, which is then transferred onto the fabric. The versatility of DTF printing allows for the use of vibrant colors and intricate designs, making it ideal for custom apparel printing. Additionally, DTF methods cater to a wide range of fabrics, opening possibilities for various applications in the fashion industry.

The DTF transfer process not only simplifies the printing operation but also streamlines production, saving time and materials. As opposed to screen printing, which often requires multiple setups for each color, the DTF process allows for full-color prints from the outset. Understanding these fundamentals gives printers a competitive edge, enabling them to produce market-ready products quickly while maintaining quality control.

The Benefits of Using DTF Gangsheets

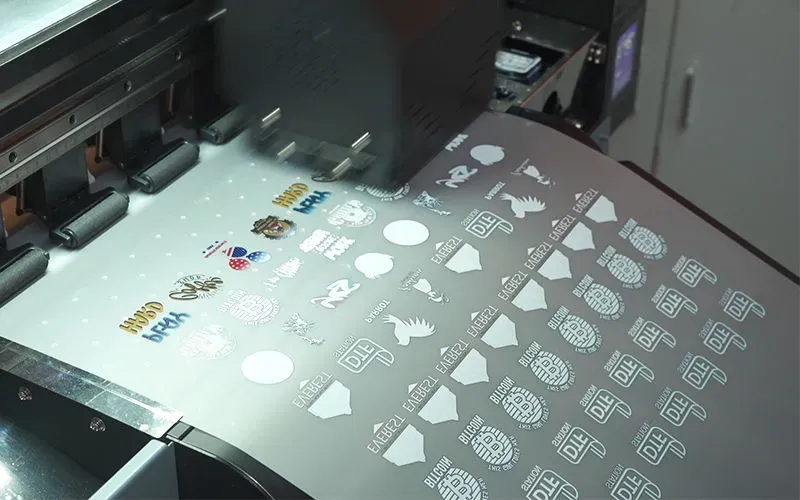

DTF gangsheets offer a multitude of benefits for businesses engaged in custom printing. By consolidating multiple designs onto a single sheet, printers can significantly reduce material waste and cut down operational costs. This approach is particularly effective for bulk orders, where efficient use of film translates directly to savings in time and resources. Furthermore, DTF gangsheets enhance productivity, allowing for quicker turnaround times without compromising on design quality.

In essence, the use of DTF gangsheets is a game changer for printers looking to optimize their workflow. The ability to print a variety of designs on one film means that companies can cater to diverse customer needs with ease. Whether it’s for promotional merchandise, personalized gifts, or team uniforms, this method not only meets market demands but also maximizes profits through efficient production strategies.

Mastering the Design Phase for DTF Printing

The first step in mastering the DTF gangsheets process begins with high-quality design. Using professional graphic design software such as Adobe Illustrator allows you to create artwork that not only meets client specifications but also aligns with the technical limitations of DTF printing. Ensuring that designs are formatted correctly, typically in PNG or TIFF formats, preserves quality and transparency in prints. High-resolution images prevent pixelation, which can detract from the final product.

Additionally, it is imperative to consider color management settings during the design phase. DTF printers predominantly operate using the CMYK color model. Therefore, designers need to familiarize themselves with how colors translate between digital formats and printed outputs, ensuring that what is visible on screen closely matches the finished print. This attention to detail can significantly improve client satisfaction and reduce revisions, creating a more streamlined workflow.

Optimizing the Printing Process for Efficiency

To achieve remarkable results when using DTF printing techniques, optimizing the printing process is crucial. Understanding the specifications of your DTF printer can enhance print quality and adhesion. Many DTF printers are equipped with specialized eco-solvent inks that are designed to bond effectively with fabric. Setting your printer to the appropriate quality settings based on the type of fabric being used ensures that the output meets the expected standards.

Additionally, selecting the correct print mode is vital for efficiency. In most cases, a double pass may be required to achieve richer colors and denser designs. By analyzing and adjusting settings such as ink saturation and speed, you can significantly improve the productivity of the printing process. Troubleshooting and fine-tuning these parameters will help in delivering artwork that meets both the artistic and functional aspects demanded by custom apparel projects.

Essential Post-Printing Techniques for DTF Transfers

Once the initial DTF printing process is completed, post-printing techniques play a vital role in ensuring that prints withstand the test of time. After applying the DTF powder adhesive while the ink remains wet, it is paramount to cure the film properly. This step solidifies the adhesive to ensure flawless transfers without compromising the integrity of the print. Utilizing a heat press or a dedicated curing oven optimizes this phase, contributing to the longevity of the print.

Moreover, proper cooling and peeling techniques are essential for a successful transfer. Allowing the fabric and film to cool slightly before peeling off the backing is crucial; doing so too early can lead to incomplete transfers, while waiting too long may make the peeling difficult. Implementing a final touch-up by pressing the design again with a protective cover sheet is recommended to enhance durability and create a professional finish. These post-printing techniques are integral to achieving high-quality results in custom apparel.

Maximizing Success with DTF Printing Tips

For printers keen on mastering the DTF gangsheets process, embracing a culture of continuous improvement can be transformative. Regular maintenance of your DTF printer is paramount; ensuring that the printer heads are clean prevents clogging, which can adversely affect print quality. Additionally, investing time in understanding the various components of DTF printing, such as ink types and film properties, rounds out your knowledge and broadens your skill set.

Conducting regular tests with different fabric types aids in refining your settings and ensuring quality outcomes across diverse projects. This empirical approach not only helps identify the best configurations but also improves your adaptability in a fast-paced industry. By actively experimenting with new designs and printing techniques, you can align your services with current market trends, positioning yourself as a versatile player in the custom apparel landscape.

Frequently Asked Questions

What is the DTF gangsheets process and how does it improve custom apparel printing?

The DTF gangsheets process involves preparing multiple designs on a single DTF film sheet, which streamlines the printing process for custom apparel. This technique reduces waste and time while maximizing production efficiency, making it a cost-effective solution for bulk orders.

How do I achieve high-quality prints in the DTF printing techniques?

To ensure high-quality prints with DTF printing techniques, start by designing artwork in high resolution (PNG or TIFF), manage your color settings accurately, and use a specialized DTF printer with the correct ink. Proper application of powder adhesive and consistent curing temperature also play crucial roles in print quality.

What are the steps involved in the DTF transfer process?

The DTF transfer process includes several key steps: 1) Design your artwork, 2) Set color management profiles, 3) Print using a DTF printer, 4) Apply powder adhesive, 5) Cure the film, 6) Transfer to fabric with a heat press, and finally, 7) Cool and peel the film to reveal the design.

What type of printer is best for the DTF gangsheets process?

A specialized DTF printer is essential for the DTF gangsheets process. These printers are designed to work with eco-solvent or DTF inks to provide vibrant colors and precise application. Make sure the printer supports CMYK color profiles for optimal results.

How do I apply the adhesive correctly in the DTF printing process?

In the DTF printing process, the adhesive must be applied immediately after printing while the ink is still wet. Ensuring even coverage of the DTF powder adhesive is crucial for effective adherence during the transfer, promoting a successful final product.

What tips can enhance my efficiency in mastering DTF gangsheets?

To enhance efficiency in mastering DTF gangsheets, maintain your printer by keeping it clean, test different fabric types with sample prints to optimize settings, and experiment with unique designs. Engaging with online DTF communities can also provide valuable insights and tips.

| Key Point | Description |

|---|---|

| Introduction | Importance of mastering the DTF gangsheets process in custom apparel printing. |

| What are DTF Gangsheets? | A method to prepare multiple images on one DTF film sheet for efficient bulk printing. |

| 1. Design Your Artwork | Use high-resolution designs in PNG or TIFF formats with graphic design software. |

| 2. Color Management Settings | Accurate color profiles in CMYK for vibrant prints. |

| 3. Printing Process | Specialized DTF printers with eco-solvent inks are required, optimized for quality. |

| 4. Applying Powder Adhesive | Must apply adhesive while the ink is wet for best results. |

| 5. Curing the Film | Cure with heat press or oven to solidify adhesive on the film. |

| 6. Transferring to Fabric | Heat press DTF film on fabric at 320°F for 15-20 seconds. |

| 7. Cooling and Peeling Process | Let film cool slightly before peeling to ensure adhesion. |

| 8. Final Touch-Up | Press the design again with a protective sheet for durability. |

| Tips for Successful DTF Printing | Regular maintenance and sample testing can improve print quality. |

Summary

The DTF gangsheets process is an essential technique in modern textile printing that streamlines the creation of high-quality designs. By understanding the intricacies of this process, including artwork design, color management, and proper printing techniques, professionals can significantly enhance their printing efficiency and design quality. This comprehensive guide not only covers the essential steps needed for successful DTF printing—from applying powder adhesive to the final touch-ups—but also emphasizes the importance of continuous learning and experimentation. As the textile industry evolves, keeping up with best practices and community insights will ensure that your DTF printing capabilities are not just adequate, but exceptional.