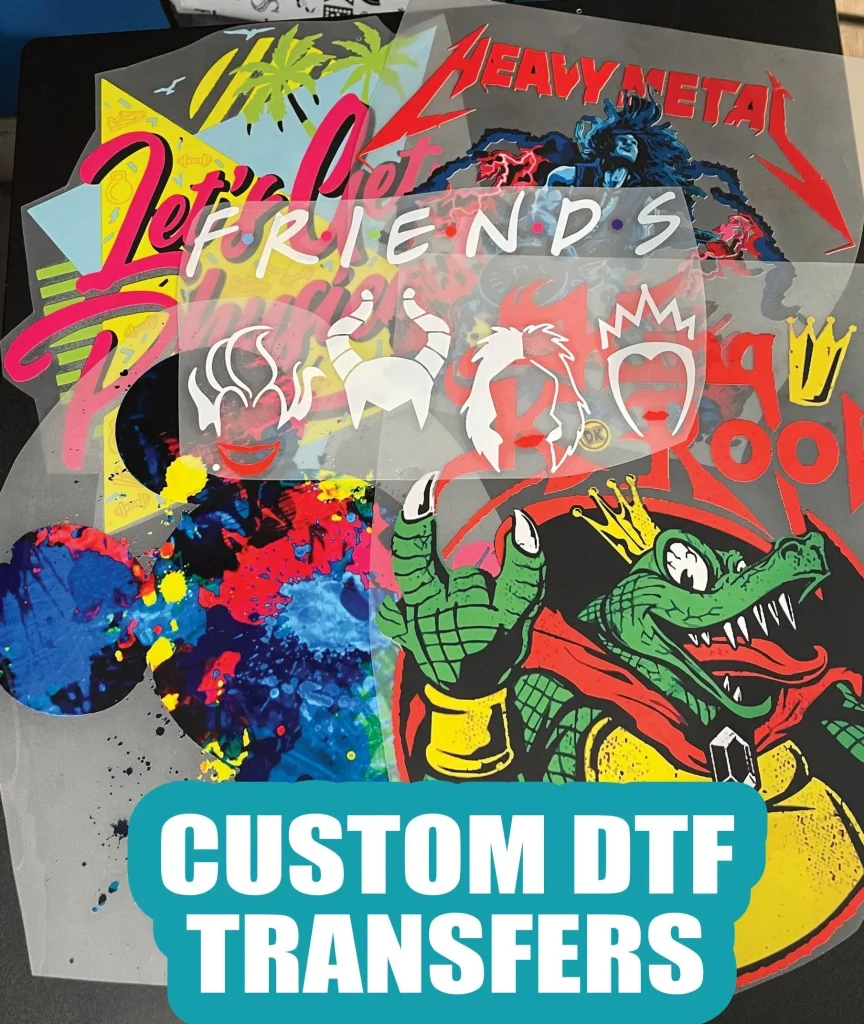

In today’s vibrant fashion scene, **DTF transfers** (Direct-to-Film transfers) have emerged as a game-changing technology, revolutionizing the world of custom apparel. This innovative printing method allows designers and businesses to create stunning, high-quality prints that cater to diverse styles while supporting the principles of sustainable fashion. Unlike traditional techniques, DTF printing excels in producing intricate designs with vibrant colors on various materials, including eco-friendly fabrics. This versatility not only enhances the aesthetic appeal but also aligns with the growing demand for sustainable and customizable solutions in the print-on-demand market. As we explore the fascinating landscape of DTF transfers, we’ll discover how this eco-conscious printing method is shaping the future of custom apparel production.

Direct-to-Film (DTF) printing is quickly carving its niche in the realm of personalized clothing, making it a preferred choice for businesses and creatives alike. Often referred to as film transfer printing, this technique allows for detailed designs to be transferred onto various textile surfaces, combining ethical production with cutting-edge technology. With a focus on environmentally friendly processes, this method minimizes waste while delivering high-quality, durable graphics that resonate with today’s consumers. As the global market for sustainable fashion continues to expand, print-on-demand services provided by DTF technology offer a perfect blend of creativity, quality, and responsibility. In this context, it’s clear that the future of custom apparel lies in the innovative use of DTF processes.

Exploring the Benefits of Custom Apparel

Custom apparel serves as a powerful means of self-expression, enabling individuals and brands to communicate their unique identities through fashion. Whether through bold graphics, intricate detailing, or personalized logos, custom clothing allows for creative freedom that mass-produced garments simply cannot compete with. This flexible medium not only enhances personal style but can also act as a robust marketing tool for businesses, helping them to stand out in a competitive landscape.

In addition to individual expression, custom apparel is becoming increasingly popular among businesses seeking to strengthen brand awareness. By utilizing high-quality materials and printing processes like DTF transfers, companies can create standout products that reflect their brand values and connect with their target audience. The growing trend towards personalization in fashion means that consumers are drawn to unique, custom pieces which sets businesses apart while enhancing customer loyalty.

Advantages of DTF Printing for Custom Apparel

DTF printing represents a significant advancement over traditional printing methods, particularly due to its versatility across different fabric types. This technology allows for high-quality prints on everything from cotton to synthetic blends and even leather. As a result, apparel creators can experiment with a wider range of materials, tailoring their designs to meet specific consumer preferences and opening avenues for innovative product development.

Moreover, DTF printing offers an eco-friendly alternative to conventional garments production techniques. By minimizing waste and optimizing the use of resources, businesses can create custom apparel that’s not only appealing but sustainable. This focus on environmental responsibility resonates with a growing demographic of consumers who prioritize eco-friendly fashion choices, ensuring that brands not only deliver quality products but also contribute positively to global sustainability efforts.

Step-by-Step Guide to Designing DTF Transfers

To create stunning custom apparel with DTF transfers, begin with a solid foundation by designing your artwork. Utilizing software such as Adobe Illustrator or CorelDRAW, designers should focus on creating high-resolution images, ensuring that every detail is captured vividly for print. Adhering to a recommended resolution of 300 DPI ensures that prints will be sharp and visually pleasing, appealing directly to the market’s expectations for quality custom apparel.

Selecting the right printer is equally critical to the DTF printing process. High-quality DTF printers cater to various needs from small businesses to larger operations, producing vibrant results while accommodating intricate designs. As the market continues to expand and modernize, investing in advanced printing technology becomes essential, ensuring businesses can meet the demands of a competitive custom apparel landscape while maintaining efficiency and design quality.

The Role of Technology in DTF Printing

The ongoing technological advancements in DTF printing are reshaping the textile industry, enhancing the efficiency and quality of custom apparel production. Innovations allow creators to produce more intricate designs in less time, adapting swiftly to market trends and consumer demands. The introduction of compact printing machines, such as A3 DTF printers, is particularly beneficial for small businesses and DIY enthusiasts, empowering them to partake in the growing trend of personalized fashion.

These technological improvements do not just lead to accelerated production times but also facilitate reduced operational costs. By merging efficiency with quality, DTF printing technology positions businesses to capitalize on opportunities in the print-on-demand market, where custom apparel is increasingly popular. This adaptability underscores the relevance of DTF printing within the sustainable fashion narrative as businesses look for ways to remain competitive while being responsible.

Sustainable Fashion Through DTF Transfers

Sustainability and fashion are increasingly intertwined, with consumers actively seeking options that reduce environmental impact. DTF transfers emerge as a frontrunner in promoting eco-friendly practices in the custom apparel industry. By producing garments with minimal waste and utilizing efficient manufacturing processes, DTF printing aligns itself with the core principles of sustainable fashion. Companies adopting this technology can appeal to eco-conscious consumers who are passionate about their purchasing choices.

Furthermore, the lightweight materials often used in DTF transfers contribute to the overall reduction of carbon footprints associated with shipping and production. Emphasizing sustainability not only meets consumer demands but also positions brands as leaders in the movement towards environmentally responsible fashion. This alignment with consumer values fosters stronger brand loyalty, ultimately driving both sales and engagement in a saturated market.

Success Stories: DTF Printing in Action

Numerous businesses have successfully integrated DTF printing into their operations, leading to remarkable improvements in customer satisfaction and brand reputation. Brands leveraging this technology have reported increased engagement from consumers, primarily due to high-quality prints that are durable and visually appealing. The capability to offer custom designs while ensuring operational efficiency has positioned these companies as innovative players in the custom apparel market.

What sets these successful businesses apart is their commitment to sustainability in production practices alongside utilizing advanced DTF printing methods. Case studies underline the advantages of this technology, with many companies fostering strong connections with their audience by emphasizing eco-friendly products. As awareness of sustainable fashion grows, businesses that incorporate DTF printing find themselves well-positioned to gain traction in a market that increasingly values responsibility alongside style.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom apparel?

DTF Transfers, or Direct-to-Film transfers, are a modern printing technique used in custom apparel that involves printing designs onto a film coated with adhesive. This film is then applied to fabric using heat and pressure, allowing for vibrant colors and intricate details to be transferred onto a variety of materials.

Why should I choose DTF printing over traditional methods for custom apparel?

Choosing DTF printing over traditional methods like screen printing or sublimation offers numerous benefits. DTF transfers provide excellent versatility across different fabric types, produce high-quality and durable prints, and support eco-friendly practices by minimizing waste, making them a preferred option for sustainable fashion.

Is DTF printing suitable for eco-friendly printing initiatives?

Yes, DTF printing is highly suitable for eco-friendly printing initiatives. The DTF transfer process reduces production waste and uses less harmful chemicals compared to traditional printing methods, aligning with the goals of sustainable fashion and environmentally-conscious consumers.

How can businesses benefit from using DTF transfers in print-on-demand services?

Businesses can greatly benefit from using DTF transfers in print-on-demand services as this technique allows for quick production of high-quality custom apparel. With the ability to print on various fabrics and produce intricate designs, companies can easily meet diverse customer demands while keeping inventory low.

What materials can be printed on using DTF transfers?

DTF transfers can be printed on a wide range of materials including cotton, polyester, leather, and various fabric blends. This versatility makes DTF printing an excellent choice for custom apparel across different styles and garment types.

What are the latest advancements in DTF printing technology?

Recent advancements in DTF printing include improvements in printer capabilities that allow for faster production, larger design options, and reduced costs. New compact A3 DTF printers are also catering to DIY enthusiasts and small businesses, enhancing accessibility to high-quality custom apparel printing.

| Key Point | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers, or Direct-to-Film transfers, are revolutionizing custom apparel by enhancing quality and promoting sustainability. |

| Advantages of DTF Transfers | 1. Versatile across various fabrics. 2. Eco-friendly and sustainable process. 3. High-quality, enduring prints. |

| Creating Custom Apparel | Steps include designing artwork, choosing a printer, preparing DTF film, applying adhesive, transferring the design, and curing it. |

| Technological Advancements | Recent innovations allow for faster production, cost reductions, and advancements in printing capabilities. |

| Sustainable Practices | DTF technology minimizes waste, aligning production with eco-friendly practices. |

Summary

DTF Transfers are transforming the custom apparel landscape, offering high-quality and vibrant designs that are both versatile across various fabrics and sustainable. This advanced technology not only prioritizes the quality and durability of prints but also aligns with the growing demand for eco-friendly production practices. As businesses and individuals increasingly recognize the benefits of DTF printing, they can create unique and impactful custom apparel that resonates with consumers and stands out in a competitive market. Embracing DTF Transfers is a strategic move for any fashion-forward brand looking to innovate responsibly.