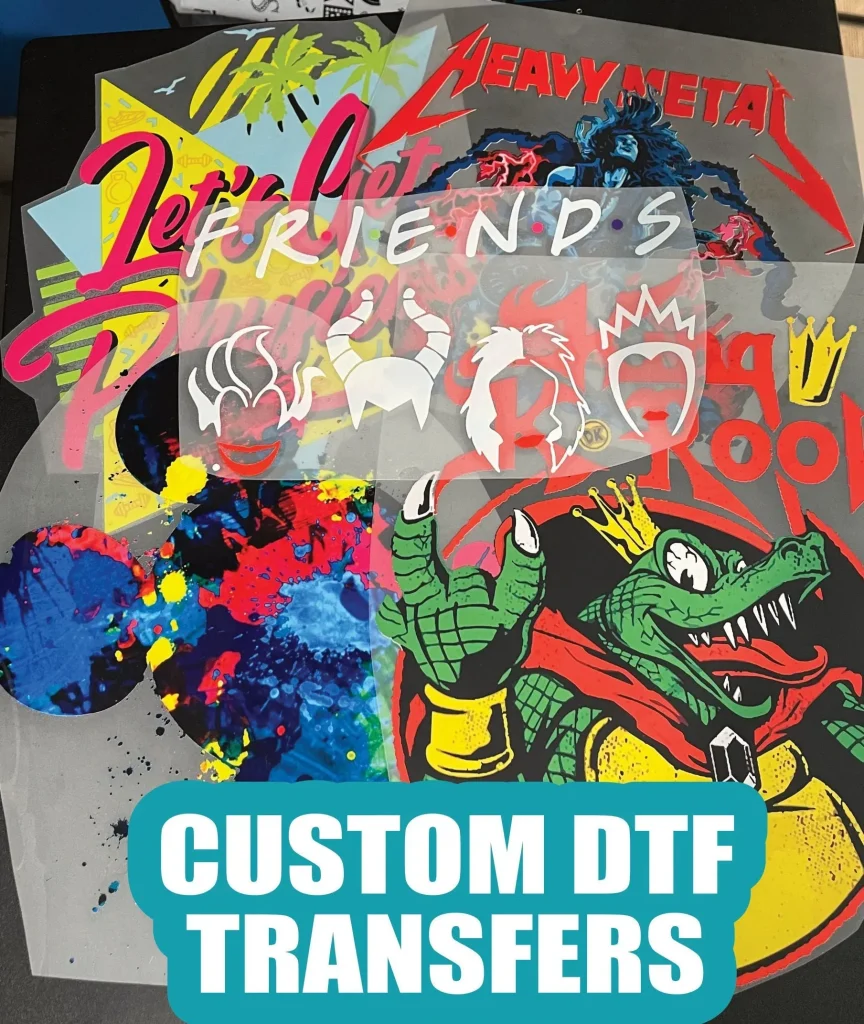

DTF Transfers, or Direct-to-Film printing, have emerged as a game-changer in the realm of custom printing. This cutting-edge technology allows for vibrant designs to be effortlessly transferred onto a variety of fabrics, offering unparalleled versatility that traditional methods lack. With DTF printing technology, designers can bring their visions to life on cotton, polyester, and blended materials, making it the go-to choice for personalized apparel and promotional products. As the industry moves towards more sustainable custom printing practices, DTF transfers are also leading the charge with eco-friendly inks and processes that reduce environmental impact. In this article, we will explore the latest innovations in DTF transfers and how they are shaping the future of the custom printing industry.

The world of direct-to-film (DTF) printing technology has recently captivated the custom printing landscape with its remarkable flexibility and durability. Often referred to as film transfer printing, this method enables creatives to apply intricate designs onto a wide range of materials, surpassing the limitations of conventional printing techniques. The rise of direct-to-film solutions is not just a technological advancement; it’s also a response to the increasing demand for personalized items in various sectors, particularly in fashion and branding. Furthermore, innovations in printing methodologies are steering the market towards more eco-friendly options, aligning with consumer preferences for sustainable custom printing. As we delve deeper, we’ll uncover how DTF transfers are setting new benchmarks in quality, efficiency, and environmental responsibility.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing is a cutting-edge method that allows for the application of intricate designs onto various fabric types. This technology uses a specialized film to transfer vibrant images directly onto surfaces, making it a superior choice for custom printing. Unlike traditional techniques such as screen printing, DTF offers greater flexibility with materials, enabling designers to produce unique pieces without the limitations of traditional methods. As more businesses lean towards personalized products, DTF printing paves the way for creativity to flourish, thus contributing to its rapid adoption in the industry.

Moreover, DTF printing technology streamlines the production process, reducing the time from design to finished product. With advancements in printing machines, modern DTF printers provide high-resolution outputs at impressive speeds. This means that custom apparel manufacturers can offer tailored solutions to their customers without sacrificing quality. As this technology evolves, it continues to raise the bar for printing standards, ensuring that customers receive top-notch products that meet their demands for personalization.

Recent Innovations in DTF Transfers

The recent developments in DTF transfer technology are reshaping the landscape of custom printing. Innovative ink formulations have emerged, designed to improve color vibrancy and durability. These inks—often environmentally friendly—make it possible to achieve stunning prints while reducing the ecological footprint of the printing process. With growing consumer awareness about sustainability, brands are increasingly attracted to these advancements, ensuring their products not only look impressive but are also socially responsible.

In addition to ink advancements, upgrades in printing equipment have transformed the DTF sector. Leading manufacturers are now offering sophisticated DTF printers equipped with higher resolutions and faster printing speeds. This technological leap enables small businesses to compete effectively against industry giants, as they can produce quality items quickly and efficiently. Such innovations also highlight the potential for growth within the custom printing market, as newly equipped businesses can take on larger orders and broaden their service offerings.

Market Trends Influencing DTF Printing

As the custom printing sector evolves, major market trends are significantly impacting DTF printing practices. One of the vital trends is the shift toward on-demand production, which is becoming increasingly popular among consumers who seek personalized options. DTF printing not only facilitates quick turnaround times but also accommodates individual design requests with ease. This responsiveness to market demands is what makes DTF transfers an attractive option for apparel businesses targeting niche markets.

Furthermore, the focus on consumer customization is reshaping manufacturing practices within the industry. Brands are recognizing the need to embrace trends that favor personalized experiences, and DTF printing is perfectly positioned to fill this gap. By utilizing this technology, businesses can offer unique designs that resonate with their clientele, ultimately driving customer loyalty and enhancing brand image.

Sustainability in DTF Custom Printing

The growing emphasis on sustainability in the printing industry cannot be overstated, particularly for DTF custom printing. As environmental concerns gain traction, manufacturers are exploring sustainable inks and materials to create eco-friendly DTF transfers. The shift towards responsibly sourced products is not just a trend; it reflects the changing priorities of consumers who are increasingly making purchase decisions based on environmental impact.

In addition, sustainable custom printing practices can significantly reduce waste within the production process. By adopting DTF technology, businesses can minimize oversupply and cut down on excess inventory, addressing the challenges of traditional printing techniques. This forward-thinking approach not only benefits the environment but also enhances the reputation of printing companies as champions of sustainability.

Challenges Faced by DTF Printing Companies

While DTF printing technology offers numerous advantages, it also presents specific challenges that companies must navigate. For many organizations, the transition from conventional methods to DTF can be daunting, particularly for those without prior experience in the digital printing arena. The learning curve associated with mastering DTF equipment and software may be steep, potentially hindering the flow of operations in the early stages.

Moreover, as businesses scale up their DTF production, maintaining high-quality standards becomes increasingly vital. Quality control issues can arise due to the varying capabilities of different printing equipment. To ensure consistency, companies must invest in reliable technology and ongoing training for their staff, ensuring that everyone is equipped with the knowledge to achieve the best possible results for their customers.

Future Innovations in DTF Transfers

The future of DTF transfers is bright, with numerous innovations on the horizon that promise to enhance this already impressive technology. Researchers are tirelessly working to develop new ink formulations and film materials that offer even greater durability and color fidelity. These advancements are crucial as they will further improve the overall quality of DTF prints, making them suitable for a broader range of applications, including high-stakes fashion and promotional items.

In addition to advancements in materials, the integration of AI and machine learning within DTF printing processes is expected to revolutionize how designs are created and executed. These technologies can optimize color matching, automate settings for different materials, and improve the reliability of production. As these innovations unfold, they will undoubtedly provide businesses with a competitive edge in the market, ensuring that DTF printing continues to push the boundaries of what is possible in custom printing.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom printing?

DTF Transfers, or Direct-to-Film Transfers, are a revolutionary method in custom printing where designs are printed onto a special film and then transferred to fabric using heat. This process allows for vibrant, high-quality images on various materials, making DTF printing ideal for personalized apparel and promotional items.

What recent innovations have improved DTF printing technology?

Recent innovations in DTF printing technology include improved ink formulations that enhance color brightness and durability, upgraded printing equipment for higher resolution and faster speeds, and advanced software integration for better design management and color accuracy. These advancements are transforming the landscape of sustainable custom printing.

How does DTF printing compare to traditional printing methods?

DTF printing offers greater versatility compared to traditional methods like screen printing or vinyl, as it can be used on a wide range of fabrics, including cotton and polyester. Unlike traditional methods, which may have limitations in design complexity and substrate compatibility, DTF transfers enable vibrant and durable prints on diverse materials.

Is DTF printing eco-friendly and sustainable?

Yes, DTF printing can be eco-friendly. Many companies are now using sustainable ink formulations and practices to reduce environmental impact. Innovations in eco-friendly inks and films are critical to the DTF printing technology’s evolution, appealing to consumers who prioritize sustainability in custom printing.

What advantages does DTF printing offer for small businesses in the custom printing market?

DTF printing provides small businesses multiple advantages, including faster turnaround times, lower production costs, and the ability to offer highly customizable products. As the DTF market continues to grow, these benefits enable small and medium-sized enterprises to thrive in a competitive landscape.

What challenges do businesses face when adopting DTF printing technology?

While DTF printing offers numerous benefits, challenges include the initial learning curve for those new to direct-to-film processes, as well as the need for effective quality control during scaling. Businesses must navigate these issues to fully leverage the potential of DTF technology in the custom printing industry.

| Key Point | Explanation |

|---|---|

| DTF Technology Overview | DTF transfers revolutionize custom printing with high versatility on various substrates like cotton and polyester. |

| Recent Innovations | Advances in ink formulations, printer technology, and software enhance quality and efficiency in DTF printing. |

| Market Trends | Shift towards on-demand production and personalized products is driving demand for DTF printing solutions. |

| Industry Impact | DTF technology is democratizing custom printing, making high-quality printing accessible to smaller businesses. |

| Challenges Ahead | Quality control and technology transition are significant challenges for new adopters of DTF printing. |

| Future Outlook | Sustainability in ink and film research will shape the DTF printing landscape going forward. |

Summary

DTF Transfers are revolutionizing the custom printing industry by enabling vibrant, durable designs that can be applied to a variety of fabrics with ease. The future of custom printing looks promising with continuous innovations in ink formulations, upgraded equipment, and advanced software solutions, ensuring that businesses can meet the growing demand for personalized products efficiently. As market trends favor on-demand production and sustainability becomes a priority, DTF transfers are poised to lead the industry, creating opportunities for both established and emerging designers.