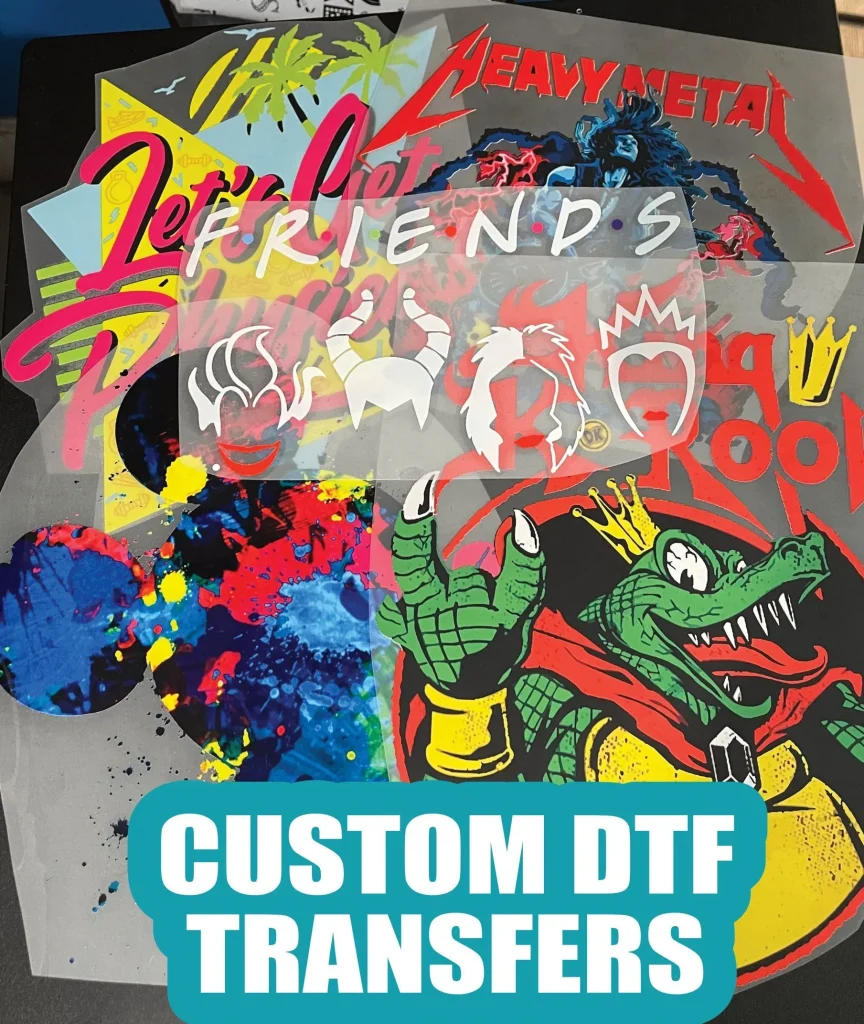

In the dynamic field of custom apparel, DTF transfers are making waves as a pivotal innovation in printing technology. Standing for Direct-to-Film printing, DTF transfers empower designers and businesses alike to create stunning, vibrant designs with incredible precision. This sustainable printing method allows intricate details to be transferred onto various garments, merging artistic expression with practicality. With its cost-effective nature and ability to cater to diverse fabric types, DTF transfers are quickly becoming the go-to choice for apparel customization. As the demand for high-quality, eco-friendly printing solutions continues to rise, DTF is perfectly positioned to shape the future of custom clothing.

Direct-to-Film printing is just one of the many revolutionary techniques enhancing the world of personalized clothing. Often referred to as DTF, this method allows for high-quality prints on an array of materials, leading the charge in apparel customization. Utilizing innovative processes, businesses can produce unique clothing items that demonstrate both style and sustainability. With an emphasis on vibrant colors and detailed designs, this printing technology is rapidly transforming how custom apparel is created and consumed. As companies embrace DTF, it’s evident that this trend extends beyond just a passing fad—it’s establishing a new standard in the garment industry.

Understanding Direct-to-Film Transfers and Their Process

Direct-to-Film (DTF) transfers represent a modern approach in custom apparel printing. The process begins with high-quality artwork that is printed onto a special DTF film using specialized printers. This innovative method allows for vibrant color reproduction and intricate design detailing that has traditionally been challenging to achieve with older printing techniques. After printing, an adhesive powder is applied to the film, which is then cured to ensure that the design adheres well to various fabrics. Once ready, the transfer can be heat pressed onto the garment, resulting in an exceptional finished product that stands out for its clarity and durability.

Unlike some other methods, DTF printing is versatile, compatible with multiple fabric types including cotton and polyester blends. This adaptability means that custom apparel businesses can meet diverse customer needs without compromising on quality. The precision offered by DTF transfers is exceptional, making it the go-to choice for businesses looking to produce high-impact designs that captivate consumers. Whether for promotional items, sportswear, or fashion statements, DTF transfers enhance the creative potential of custom clothing.

Quality Advantages of DTF Transfers

The quality of prints produced by DTF transfers sets them apart from traditional screen printing methods. DTF technology excels in delivering vibrant colors that are strikingly bright and accurately reproduce the design’s original hues. This capability enhances the visual appeal of custom apparel, attracting consumers who are drawn to eye-catching designs. Additionally, the detail achievable with DTF printing is remarkable. Fine lines and small elements within a design maintain their integrity during the transfer process, ensuring that each printed piece reflects the artist’s vision.

Moreover, DTF transfers apply a unique adhesive that bonds the ink firmly to the fabric, which not only enhances durability but also ensures that the designs withstand the rigors of washing and everyday wear. As a result, businesses can market their apparel with confidence, knowing they are providing customers with products that maintain their quality over time. For companies invested in customer satisfaction and reputational quality, adopting DTF transfers can significantly improve the appeal of their product offerings.

Cost Efficiency and DTF Printing

One of the most appealing aspects of DTF transfers is their cost-effective nature, particularly for businesses engaged in small to medium production runs. Traditional screen printing requires a separate screen for each color — a costly and time-consuming process that can hinder quick order fulfillment. In contrast, DTF printing eliminates the need for multiple screens, allowing designs to be printed simultaneously in a much simpler manner. This reduction in production steps allows businesses to save money and time, crucial factors for any company seeking to enhance profitability.

Additionally, the faster setup and shorter production times associated with DTF printing mean that businesses can better respond to consumer demands, especially for custom orders. This flexibility allows brands to capitalize on trends and personalizations that the market craves, without sacrificing their bottom line. In a competitive landscape where responsiveness often drives sales, utilizing DTF transfers can provide businesses with a significant advantage, marking a shift towards leaner operational practices in custom apparel production.

Sustainable Practices in DTF Transfers

As the demand for eco-friendly products rises, DTF transfers stand out for their sustainable printing practices. Many DTF printing methods utilize water-based inks, which offer a less harmful alternative to the plastisol inks prevalent in traditional screen printing. By prioritizing sustainability, businesses can align with the values of environmentally conscious consumers, ensuring that their product choices resonate with buyers who prioritize eco-friendliness in their purchasing decisions.

Furthermore, the efficiency of the DTF printing process contributes to its sustainability. The reduced need for ink and material waste, combined with the longer lifespan of the printed designs, minimizes the environmental impact compared to more traditional methods. Companies emphasizing sustainable practices not only enhance their brand reputation but also reach a growing market segment that prefers products that match their values, thus driving sales and loyalty in the process.

The Growing Adoption of DTF Technology

The recent surge in the availability of DTF printers has made this technology increasingly accessible to small and medium-sized enterprises (SMEs) within the custom apparel industry. As these printers become more affordable, many businesses that traditionally relied on older printing methods are now integrating DTF technology into their production lines. This dramatic shift is not solely about cost savings; it represents a broader trend towards enhanced personalization and customization capabilities that are vital in today’s consumer landscape.

The enhanced ability to customize products has become a key selling point for many brands, and DTF printing facilitates this by allowing for quicker turnaround times on orders. As small businesses adopt DTF technology, they can compete effectively with larger brands, offering unique, high-quality apparel that meets consumers’ growing demand for personalized clothing. This trend toward customization will keep shaping the market, ensuring that DTF printing remains a critical player in the future of apparel production.

Future Innovations in DTF Printing

Looking ahead, the future of DTF printing is full of potential innovations and advancements. Industry experts predict that developments in curing technologies will lead to faster curing times, allowing businesses to enhance their production efficiencies even further. As the technology matures, we can expect to see improved ink formulations that not only raise the quality of prints further but also expand the range of fabrics that can be utilized, broadening the scope of custom apparel options for businesses.

Additionally, advancements in machinery will likely streamline the DTF printing process. Companies are continuously seeking ways to optimize workflows and reduce costs, and innovations in printing technology promise a future where DTF transfers can be produced even more efficiently. As DTF becomes integrated into the mainstream production lines of custom apparel, those adopting these innovations first will undoubtedly have a head start in catering to the evolving demands and preferences of consumers.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, utilize specialized printers to print designs onto a unique film. An adhesive powder is applied to bond the vibrant and intricate designs to various fabrics. This technology allows for high-quality custom apparel that showcases bright colors and fine details, making it a preferred choice in the printing industry.

Why are DTF transfers becoming a popular choice for sustainable printing?

DTF transfers are gaining traction in sustainable printing because they primarily use water-based inks that are less harmful to the environment compared to traditional plastisol inks. This eco-friendliness appeals to consumers who prioritize sustainability, facilitating a growing market for custom apparel that aligns with environmentally conscious values.

How do DTF transfers compare to traditional printing methods for custom apparel?

Compared to traditional printing methods like screen printing, DTF transfers offer superior versatility and quality. They allow for intricate designs and vibrant color reproduction on various fabrics without the need for multiple screens, making them more cost-effective and quicker for custom apparel production.

What advantages do DTF transfers offer for businesses involved in custom apparel?

DTF transfers provide multiple advantages for businesses, including cost-efficiency due to no screens required, faster turnaround times for fulfilling orders, and the ability to print on a wide range of materials. This makes DTF technology an excellent investment for companies looking to enhance their custom apparel offerings.

What future trends can we expect in DTF printing technology for custom apparel?

The future of DTF printing technology in custom apparel includes innovations like faster curing methods, improved ink formulations for better durability, and enhanced efficiency in production processes. These trends will likely solidify DTF as a leading choice in apparel customization for years to come.

Can DTF transfers be used on any type of fabric for custom apparel?

Yes, DTF transfers are versatile and compatible with various fabric types, including cotton, polyester, and blends. This broad applicability makes DTF technology a favored method for producing high-quality custom apparel that meets diverse consumer preferences.

| Key Point | Description |

|---|---|

| DTF Transfers Definition | Direct-to-Film (DTF) is a printing method where designs are printed onto a special film and then transferred to fabrics using heat and adhesive. |

| Quality and Versatility | DTF transfers deliver vibrant colors, intricate details, and compatibility with various materials like cotton and polyester. |

| Cost-Efficiency | DTF eliminates the need for screens, reducing costs and enabling faster turnaround on custom orders. |

| Eco-Friendliness | Utilizes water-based inks, making it a more environmentally friendly option compared to traditional methods. |

| Increased Adoption and Availability | Advancements in technology have made DTF printers more affordable, allowing small businesses to thrive. |

| Future Outlook | Expect ongoing advancements in curing methods, ink quality, and efficiency enhancing DTF processes. |

Summary

DTF transfers are revolutionizing the custom apparel landscape with their innovative printing capabilities. This method stands out due to its ability to produce high-quality, vibrant designs that can be printed on various fabrics, making it an ideal choice for businesses looking to offer customized solutions. The combination of cost-effectiveness, environmental sustainability, and ease of access for small businesses underlines the growing significance of DTF transfers. As the technology continues to evolve, it is clear that DTF will play a crucial role in the future of custom clothing, meeting diverse consumer demands with precision and efficiency.