In the realm of custom apparel, DTF transfers have emerged as a game-changing technique that enhances the quality and appeal of garments. Known as Direct to Film printing, this innovative approach allows for vibrant, high-resolution designs to be applied to fabrics with ease and efficiency. As businesses strive to meet the demand for unique and personalized clothing, understanding the benefits of DTF transfers becomes paramount. This method not only provides versatility across various fabric types, but also ensures longevity and durability, making it an ideal choice for decorators. With the advancements in DTF printing technology, it’s evident that this is a trend that is here to stay in the custom apparel industry.

Direct to Film printing, often referred to as DTF transfer printing, is revolutionizing the way custom apparel is created and decorated. This technology enables designers to print intricate graphics directly onto a special film, which is then heat-pressed onto garments. By utilizing DTF techniques, businesses can achieve stunning, full-color prints on a wide array of materials, appealing to the ever-growing market for personalized apparel. The advancements in DTF printing not only streamline production but also enhance the finish quality, providing an advantage over traditional methods. As the demand for customized clothing rises, the exploration of DTF transfer benefits is becoming increasingly relevant.

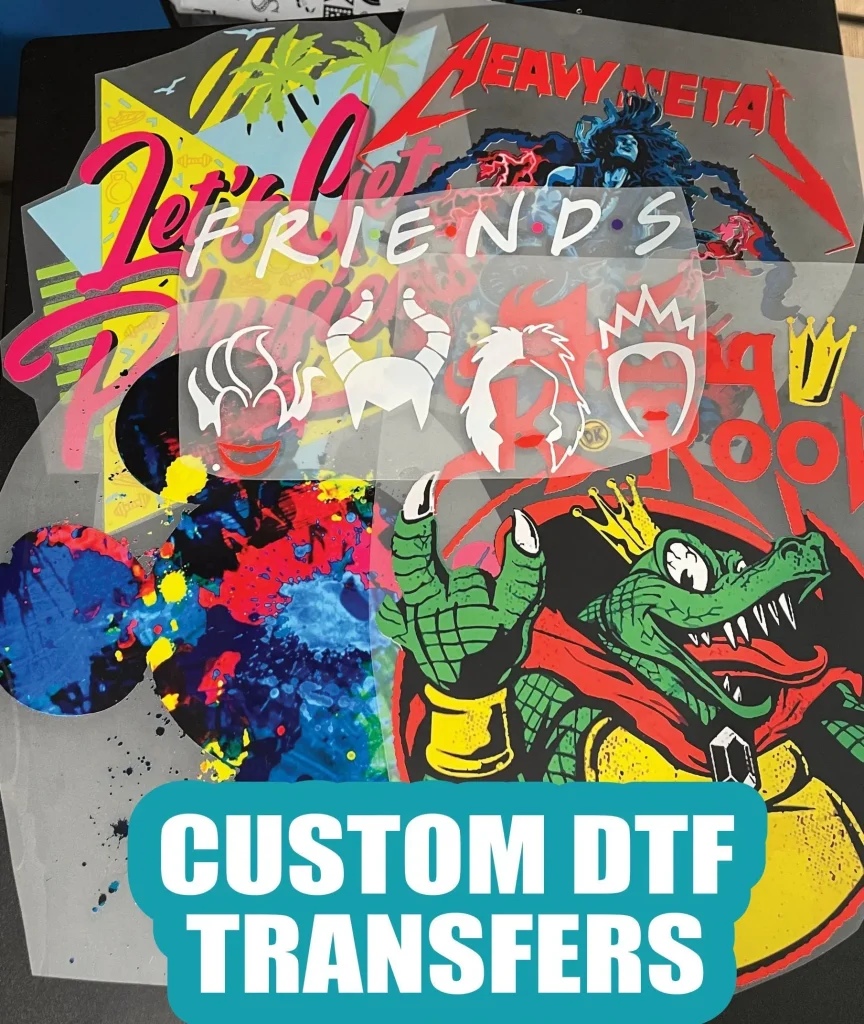

Understanding DTF Transfers: A Game Changer for Custom Apparel

Direct to Film (DTF) transfers are redefining the landscape of custom apparel decoration. This innovative printing method involves applying designs directly onto a film that can then be transferred onto various fabrics. The process employs heat and pressure, making it ideal for producing vibrant, high-quality images. By allowing intricate designs to shine, DTF printing meets the rising demand for personalized apparel that stands out in a sea of generic options.

In essence, DTF transfers combine the advantages of traditional screen printing and digital printing, creating a bridge to cater to modern customer needs. This method not only supports a broader range of fabrics—from cotton to blends—but also ensures that colors remain true and bold, thus enhancing overall product appeal. Businesses engaged in custom apparel should consider the versatility and quality of DTF printing as a valid option for meeting their consumers’ diverse needs.

Benefits of DTF Printing Technology for Custom Apparel

The benefits of DTF printing technology are substantial and can significantly impact business growth within the custom apparel market. One of the primary advantages is its efficiency and speed; DTF transfer printing allows for rapid production of designs, which is invaluable in meeting consumer demands quickly. Businesses can prepare designs digitally and produce multiple transfers swiftly, giving them a competitive edge in a fast-paced environment.

Additionally, DTF transfers are known for their durability. Unlike many other printing methods, DTF prints are washed several times without fading, ensuring that the apparel maintains its vibrant appearance long after purchase. This aspect is particularly appealing to consumers who seek long-lasting products that offer value for money. By leveraging the benefits of DTF printing technology, businesses can enhance customer satisfaction and loyalty.

Exploring the Versatility of DTF Transfers Across Fabrics

DTF transfers boast remarkable versatility, making them suitable for various types of fabrics. This capability allows businesses to expand their offerings; whether using cotton, polyester, or blended materials, DTF printing can adapt to the specific characteristics of each fabric type. This flexibility opens up diverse opportunities to create unique apparel that caters to various audiences, from sportswear to fashion garments.

Moreover, the ability to print on a wide array of substrates expands the creative horizons for designers and entrepreneurs in the custom apparel industry. DTF transfer printing is not restricted to pre-defined fabric patterns or types, allowing endless personalization opportunities. This adaptability can attract a broader customer base, propelling businesses to innovate and differentiate themselves in a crowded marketplace.

The Eco-Friendly Benefits of DTF Transfer Printing

As environmental concerns continue to mount, many businesses are seeking sustainable printing solutions. DTF transfer printing utilizes water-based inks, which are significantly more eco-friendly compared to solvent-based options commonly used in other traditional printing practices. This shift towards greener printing technologies is increasingly appealing to consumers, who prefer purchasing from brands that demonstrate environmental responsibility.

Embracing DTF technology as part of a sustainable business model not only contributes to a reduced ecological footprint but also aligns the brand with consumer values. By choosing eco-conscious materials and practices, businesses can build a positive image, attracting environmentally aware customers and creating brand loyalty in a market increasingly oriented towards sustainability.

The Rise of DTF Printing: Market Growth and Trends

The DTF printing market is witnessing substantial growth, spurred by the escalating demand for unique custom apparel. E-commerce platforms have particularly fueled this trend, allowing customers access to personalized products that resonate with their style. As a result, brands are busily adopting DTF technology to keep up with consumer expectations for variety and quality, making it a pivotal moment for the custom apparel industry.

Moreover, increased accessibility to DTF printing technology allows small and medium-sized businesses to effectively compete with larger corporations. The democratization of this printing method amplifies market diversity and provides entrepreneurs with the tools necessary to enter the custom apparel sector. As the market evolves, staying updated with DTF trends will be integral for businesses aiming to capitalize on emerging opportunities.

Harnessing Community Support for DTF Printing Success

The DTF printing community has become an invaluable resource for both newcomers and seasoned professionals in the custom apparel industry. Online forums, social media groups, and dedicated blogs facilitate sharing tips, troubleshooting advice, and practical insights. This collaboration enables businesses to enhance their skills and stay informed about best practices, enriching the overall DTF printing experience.

Furthermore, participation in community events and educational workshops allows individuals to connect with industry leaders, creating networking opportunities that can lead to partnerships or mentorships. As the DTF printing landscape continues to grow and evolve, fostering a strong community not only benefits businesses individually but also contributes to collective knowledge and innovation within the sector.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel?

Direct to Film (DTF) transfers are a modern printing technique where designs are printed onto a specialized film that is later transferred to fabric using heat and pressure. This method allows for vibrant, high-quality prints suitable for various fabric types, making it a popular choice for custom apparel.

What are the benefits of using DTF transfer printing for custom apparel?

The benefits of DTF transfer printing include versatility on different fabric types, high-quality prints with intricate designs, faster production efficiencies, lower setup costs, excellent durability, and eco-friendly options with water-based inks. These advantages make DTF transfers a go-to solution for custom apparel decorators.

How does DTF printing technology compare to traditional screen printing?

DTF printing technology outperforms traditional screen printing in several areas, including print quality and versatility. While screen printing can struggle with complex images, DTF transfers produce vibrant colors and detailed designs on a variety of fabrics without the high setup costs associated with screens.

Is DTF transfer printing suitable for all fabric types?

Yes, one of the standout benefits of DTF transfer printing is its versatility; it can be applied to multiple fabric types, including cotton, polyester, and blends. This flexibility allows businesses to cater to diverse custom apparel needs.

What advancements are currently being made in DTF transfers?

Recent advancements in DTF printing technology include the development of faster machines, improvements in print quality, and expanded access to educational resources. These developments are enhancing efficiency and user experience, making DTF transfers increasingly appealing for businesses in custom apparel.

How eco-friendly are DTF transfers compared to other printing methods?

DTF transfers are considered more eco-friendly than many traditional printing methods, particularly due to the use of water-based inks. This sustainable practice aligns with the growing demand for environmentally responsible custom apparel options.

| Benefit | Description |

|---|---|

| Versatility on Fabric Types | DTF transfers can be applied to various materials, including cotton, polyester, and blends, making them suitable for a wide range of apparel. |

| High-Quality Prints | Produces vibrant, detailed designs that can include complex images and gradients, enhancing visual appeal. |

| Efficiency and Speed | Allows for quick production turnaround, helping businesses meet customer demands effectively. |

| Lower Setup Costs | Reduces initial costs for small businesses, enabling immediate printing without extensive preparation. |

| Durability | Ensures designs maintain quality after multiple washes, appealing to consumer demands for lasting products. |

| Eco-Friendly Options | Water-based inks used in DTF are a more sustainable choice compared to solvent-based alternatives common in other printing methods. |

Summary

DTF transfers are revolutionizing the custom apparel market by providing a versatile, high-quality, and cost-effective printing solution. This innovative method allows for a greater selection of fabric types, ensuring that businesses can cater to diverse consumer preferences. The durability and eco-friendliness of DTF printing further enhance its appeal, making it an excellent choice in today’s environmentally conscious market. As technology continues to advance, DTF transfers will likely become even more integral to the world of custom apparel, offering businesses significant advantages in production efficiency and design quality.