In the ever-evolving landscape of custom apparel printing, DTF transfers have emerged as a groundbreaking technique that combines innovation with practicality. Unlike traditional printing methods such as screen printing and direct-to-garment (DTG) printing, DTF transfers utilize a unique approach by applying designs directly from a special film onto the fabric, resulting in high-quality outputs that are both vibrant and long-lasting. The advantages of DTF printing are numerous, making it an attractive option for businesses seeking to cater to diverse customer needs while reducing costs. Not only does DTF excel in functionality and adaptability to various materials, but it also promises quicker turnaround times and minimal waste compared to its traditional counterparts. As we explore this exciting technology further, we will delve into what makes DTF transfers a preferred choice for today’s custom apparel market.

Direct-to-Film (DTF) printing, sometimes referred to as digital film transfers, has started to redefine the way businesses approach custom clothing production. This innovative method stands alongside other popular techniques such as screen printing and DTG but offers distinct benefits that can significantly enhance workflow and output quality. Many apparel brands are discovering the potential of digital film technology, which allows for complex designs to be quickly reproduced with high vibrancy. Additionally, the adaptability of DTF to a wide range of fabrics makes it a versatile tool for those looking to meet diverse market demands. By understanding these alternative terms and their implications, businesses can better navigate their printing options and choose the best technology for their needs.

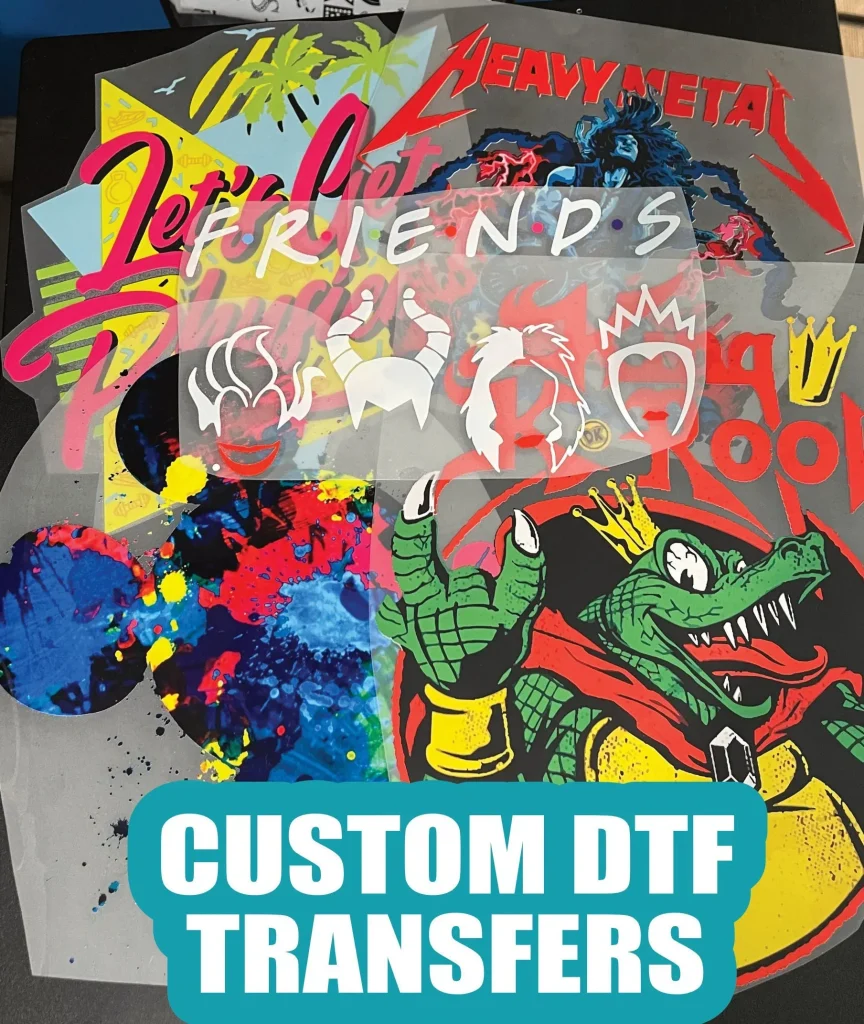

The Advantages of DTF Transfers for Custom Apparel

Direct-to-Film (DTF) transfers are revolutionizing the custom apparel printing landscape, presenting numerous advantages over traditional printing techniques. DTF printing allows for vibrant, high-quality designs that maintain their integrity after multiple washes, making it particularly appealing for custom apparel. The method is versatile, enabling users to print on various materials, including cotton, polyester, and blends, which is a significant improvement over traditional methods like screen printing that may struggle with such fabric diversity.

Moreover, DTF transfers provide faster production times, particularly beneficial for small businesses or those with custom order demands. Unlike traditional screen printing that often involves lengthy setup processes and requires specific conditions for different fabrics, DTF allows for quick execution with minimal downtime. This efficiency not only meets customer demand for rapid turnaround but also minimizes waste, making DTF an attractive option for eco-conscious businesses.

Comparing DTF Printing to Screen Printing

Screen printing has been a long-standing choice in the custom printing industry, revered for its reliability and ability to produce consistent, high-volume results. However, when placed alongside DTF printing, it becomes evident that DTF offers several key advantages. For instance, DTF transfers require less setup time and cost, especially when dealing with intricate designs or smaller quantities. This means that businesses no longer need to commit to large orders just to justify the initial investment in screen setup.

Furthermore, while screen printing uses a limited color palette due to its reliance on specific inks and create screens for each shade, DTF printing employs a broader spectrum, allowing for complex, multi-colored designs on garments with ease. For businesses looking to cater to diverse customer needs with unique designs, DTF presents a more flexible and economically viable solution.

The Rising Trend of Direct-to-Garment (DTG) Printing

Direct-to-Garment (DTG) printing is another noteworthy traditional printing method that has its own strengths, particularly for detailed designs and color accuracy. However, DTF printing has matched and even surpassed DTG in various scenarios, especially when considering fabric compatibility and production speed. While DTG printing works best on cotton fabrics, DTF excels on a range of textiles, including those that are often challenging for traditional DTG methods.

As businesses strive for efficiency, DTF technology allows for more straightforward design transfers without the risk of clogging due to various ink formulations used in DTG printing. This aspect not only enhances the operation’s overall workflow but also reduces the likelihood of needing frequent maintenance, making DTF as an appealing alternative, especially for those entering the custom printing market.

Cost-Effectiveness of DTF Transfers

One of the pivotal factors any business considers when choosing a printing method is cost-effectiveness. DTF printing shines in this area, especially for businesses that may not have the capital to invest heavily in the traditional screen printing setup. With minimal upfront costs, DTF creates opportunities for both small businesses and startups to compete in the custom apparel market without incurring substantial financial risks.

Additionally, the lower operational costs associated with DTF printing—such as reduced ink consumption and shorter print times—represent significant savings for businesses focused on maximizing profit margins. As highlighted in industry reports, quicker production rates combined with the ability to produce quality work on demand is reshaping how businesses operate, allowing them to keep inventory low while still meeting customer expectations.

Quality and Durability of DTF Prints

Quality is a non-negotiable aspect of custom apparel printing. DTF printing has gained a reputation for producing vibrant and durable prints that can withstand the test of time. Unlike some traditional methods that may fade or crack after repeated wear and laundering, DTF prints adhere well to fabric fibers, ensuring that designs remain intact for extended periods. Customers expect durability, especially when investing in custom pieces, and DTF consistently meets and often exceeds these expectations.

However, the quality of DTF prints is also heavily influenced by the quality of inks and materials used in the process. Selecting high-grade inks and reliable suppliers is essential to ensure that the longevity and vibrancy of the print are maintained. Studies show that businesses that prioritize these elements can significantly enhance their product offering, resulting in positive customer feedback and repeat business.

Embracing Sustainability with DTF Printing

In the current landscape where environmental sustainability is increasingly important, businesses are reassessing their printing methods. DTF printing has emerged as a more ecologically responsible choice compared to some conventional methods. With advancements in technology and the use of eco-friendly inks, the DTF process produces less waste and utilizes lower energy compared to traditional screen printing, which often involves more extensive resources.

Furthermore, businesses that adopt DTF printing can appeal to the growing market segment that prioritizes sustainability in their purchasing decisions. By choosing DTF printing, companies not only contribute to environmental conservation efforts but also gain a competitive edge, positioning themselves as forward-thinking brands committed to reducing their carbon footprint.

Frequently Asked Questions

What are the advantages of DTF transfers over traditional printing methods?

DTF transfers offer several advantages over traditional printing methods like screen printing and DTG. These include better compatibility with various fabric types, especially polyesters, and more vibrant, complex designs. DTF is also typically more cost-efficient, requiring lower setup costs and reduced waste, making it ideal for small businesses and custom apparel printing.

How does DTF printing compare to screen printing in terms of cost efficiency?

In terms of cost efficiency, DTF printing often outshines screen printing. Unlike traditional screen printing, which incurs significant upfront costs for screens and setups, DTF has lower entry costs, allowing for quicker turnaround times and minimal waste. This makes DTF a preferred choice for on-demand production, especially for custom apparel printing needs.

Is DTF printing suitable for all fabric types compared to traditional methods?

Yes, DTF printing is highly versatile and can effectively print on a wider range of fabrics than many traditional methods, including screen printing. This includes polyester blends and dark fabrics, where traditional techniques may struggle. This capability enhances DTF’s appeal for custom apparel printing across various materials.

What is the print quality of DTF transfers compared to direct-to-garment (DTG) printing?

DTF transfers deliver comparable print quality to direct-to-garment (DTG) printing. Both methods produce vibrant colors and fine details. However, DTF prints are particularly praised for their durability and adherence to fabric, ensuring that designs retain their quality even after multiple washes, similar to DTG outcomes.

Are DTF transfers easy to use for beginners in the custom apparel printing industry?

Yes, DTF transfers are considered beginner-friendly. Unlike traditional screen printing, which often requires specialized skills and technicians, DTF printing can be mastered with basic training. This accessibility allows newcomers in the custom apparel printing industry to quickly adopt DTF technology and start producing quality prints.

How does DTF printing impact the environment compared to traditional printing methods?

DTF printing can be more environmentally friendly compared to traditional methods like screen printing. Studies suggest that by using eco-friendly inks and materials, DTF can result in less waste and lower energy consumption per print, making it a sustainable choice for businesses looking to reduce their carbon footprint in the custom apparel market.

| Aspect | DTF Transfers | Traditional Methods |

|---|---|---|

| Functionality | Highly versatile; compatible with various substrates. | Great for high volume orders; better suited for certain fabrics. |

| Cost Efficiency | Lower upfront costs; ideal for small businesses and on-demand printing. | Higher initial investment required; not cost-effective for small runs. |

| Quality | Produces vibrant, durable prints; comparable to DTG. | Known for fine details but may vary with setup and ink quality. |

| Ease of Use | User-friendly; minimal training needed to operate. | Requires skilled technicians for setup and operation. |

| Environmental Impact | More sustainable options available; lower energy consumption. | Higher energy consumption and waste in production. |

Summary

DTF Transfers are revolutionizing the custom apparel industry with their innovative printing technology that balances quality, versatility, and cost efficiency. As businesses navigate the competitive landscape of custom printing, DTF transfers offer significant advantages over traditional printing methods. This modern approach facilitates high-quality designs on various fabrics with less waste and lower initial investments, making it an ideal choice for smaller businesses and custom orders. In conclusion, for those seeking flexibility and sustainability in their printing processes, DTF transfers represent a promising solution, setting a new standard in the realm of custom apparel.