DTF troubleshooting has become essential for achieving reliable, vibrant transfers across a range of fabrics. Understanding DTF printer settings can prevent costly reprints. Attention to DTF film quality and careful ink management helps maintain color integrity and wash-fastness. By following practical DTF quick fixes, you can resolve common problems without wasting time or materials. This approach keeps production flowing and ensures each design endures through multiple washes.

From a terminology perspective, the topic extends beyond lab jargon into direct-to-film workflow optimization and transfer-adhesion challenges. Other terms you might encounter include print-quality optimization, film integrity checks, heat-press calibration, and color management for textile applications. By framing the issue through substrate compatibility, adhesive powder behavior, and ink cure consistency, readers can connect troubleshooting steps to real-world outcomes. In practice, this broader lens helps teams diagnose root causes—from material variability to equipment setup—and apply preventive measures that keep production steady. Adopting this language also aligns content with search intent, guiding readers toward practical solutions rather than theory.

DTF Troubleshooting Essentials: Diagnosing Common Issues

DTF troubleshooting begins with a structured diagnostic mindset. When transfers don’t come out as expected, start by inspecting the most common culprits: the transfer film, adhesive powder, print settings, and heat/pressure during the final transfer. By focusing on DTF transfer issues as an integrated system, you can quickly identify whether the problem stems from ink behavior, film quality, or post-press handling, rather than treating each symptom in isolation. A careful assessment of the source file, the path of the ink, and the application of the powder will often reveal the root cause without expensive reprints.

Next, perform a practical check on your setup before reprinting. Verify that the garment is pre-pressd flat, the transfer is aligned, and your heat press is calibrated to the manufacturer’s specifications. Keep a simple diagnostic log, noting any recurring patterns such as specific fabrics, colors, or films that fail. This approach aligns with a disciplined troubleshooting workflow that reduces downtime and reinforces consistency across production runs. By treating DTF troubleshooting as a repeatable process, you’ll be equipped to diagnose issues quickly and plan effective quick fixes.

Optimizing DTF Printer Settings for Consistent Results

Printer settings play a pivotal role in achieving reliable DTF transfers. Fine-tuning parameters like dpi, color density, white underbase usage, and pass count can dramatically impact color vibrancy and edge sharpness. When you optimize DTF printer settings, you also improve the behavior of the ink, which helps minimize blurring, banding, or ghosting that can appear as DTF transfer issues on fabrics with varying textures.

To sustain consistency, establish standard profiles for each film and garment type, and update them whenever new inks or films are introduced. Regular nozzle checks and periodic printhead maintenance should be incorporated into your routine, as clogged or degraded nozzles directly affect color density and print stability. By aligning printer settings with material specifications and keeping records of successful configurations, you reduce variability and support predictable outcomes across production batches.

Ensuring DTF Film Quality to Prevent Transfer Problems

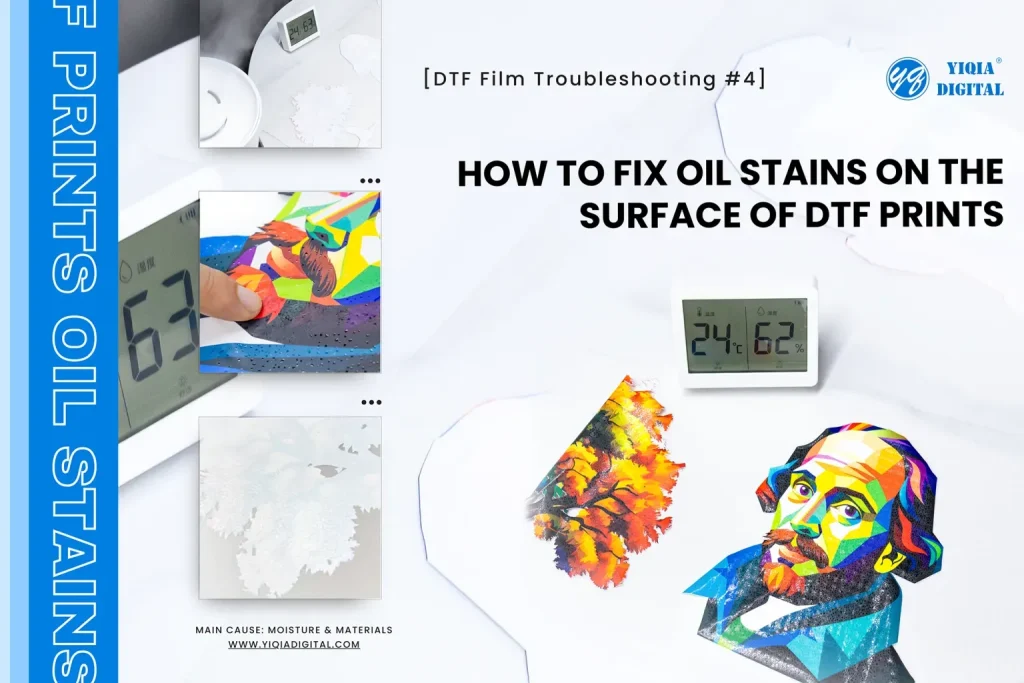

DTF film quality is a foundational factor in successful transfers. Scratches, dust, moisture, or batch-to-batch variations can all manifest as adhesion problems, color shifts, or halos around the design. Assessing film integrity before each run helps you catch issues that could otherwise compromise transfer quality. In addition, consistent storage and handling practices minimize moisture uptake and static, which can affect powder adhesion and final image clarity.

Build film quality into your workflow by inspecting each new batch for uniform thickness, smooth surface, and minimal curl. Keep records of film batch numbers and correlate results with ink behavior and powder performance to detect subtle trends over time. When film quality is controlled, the risk of DTF transfer issues drops significantly, enabling smoother pre-press and transfer cycles.

Addressing DTF Ink Problems for Vivid, Durable Prints

Ink behavior drives color fidelity and wash-fastness in DTF printing. Common ink problems include color drift, low saturation, and premature drying or blooming, which can produce pale designs or fuzzy edges. Understanding how ink viscosity, pigment loading, and cure profiles interact with your substrate helps you prevent these issues at the source rather than after a failed wash.

Combat ink problems by using fresh, properly stored inks and verifying that color management workflows align with your printer and film. Regularly perform maintenance cycles and follow manufacturer recommendations for cleaning and nozzle operation. Calibrate your curing process to ensure inks reach the required adhesion and wash durability without over-curing delicate colors. With disciplined ink management, you’ll see stronger color reproduction and longer-lasting transfers.

Practical DTF Quick Fixes for Everyday Production

DTF quick fixes are designed to salvage runs with minimal downtime. When adhesion is lacking, re-check the powder coating and re-bake within the recommended temperature window. If colors wash out, revisit color profiles and ensure you aren’t over-drying the film, which can dull the lift. These small adjustments can often restore performance without starting a new print run.

For misalignment or ghosting, re-check alignment marks and ensure the garment is flat and pre-pressed before applying the transfer. If there’s film creasing, reseat the transfer on a flat surface and apply even pressure with the correct temperature and dwell time. Keeping a reference checklist of quick fixes helps your team respond rapidly to the most frequent transfer hiccups and maintain momentum in production.

Preventive Maintenance and SOPs to Reduce DTF Transfer Issues

Prevention reduces the frequency and severity of DTF transfer issues. Create a maintenance calendar that covers weekly nozzle checks, monthly printhead cleanings, and quarterly calibration of heat presses and platen pressures. By scheduling routine care, you minimize unexpected downtime and extend the life of your printer, film, and powders.

Develop clear standard operating procedures (SOPs) for every stage—from artwork preflight to post-transfer inspection—and train staff to follow them consistently. Maintain an issue log that links results to settings, materials, and operators so you can identify recurring patterns and implement preventive improvements. With robust SOPs and proactive maintenance, your production can sustain high-quality transfers with fewer interruptions and better predictability.

Frequently Asked Questions

What is DTF troubleshooting and how does it help prevent DTF transfer issues?

DTF troubleshooting is a structured diagnostic process used to identify and fix issues that can prevent perfect transfers. It covers reviewing artwork, DTF film quality, adhesive powder freshness, DTF printer settings, heat and pressure during transfer, and proper curing. By following a consistent troubleshooting workflow, you minimize DTF transfer issues and reduce wasted materials and time.

In DTF troubleshooting, which DTF printer settings should you review to resolve transfer issues?

Check DPI, color density, white underbase usage, nozzle health, and routine maintenance. Ensure printer settings align with your film and ink specifications, run test prints, and adjust profiles as needed to eliminate transfer issues.

Why is DTF film quality important in DTF troubleshooting, and how can it affect transfers?

Film quality influences adhesion, color clarity, and wash-fastness. During DTF troubleshooting, inspect film for scratches, moisture, dust, and batch consistency; replace as needed, and verify storage conditions. Pair with correct adhesive powder and curing to prevent issues like dull prints, poor adhesion, or peeling.

What DTF ink problems should you look for in DTF troubleshooting, and what are quick fixes?

Common DTF ink problems include color drift, fading, clogging, and poor washfastness. In troubleshooting, check ink viscosity, nozzle status, color management, and curing. Quick fixes: clean printheads, use fresh ink, verify storage and profiles, and adjust cure parameters before reprinting.

During DTF troubleshooting, what DTF quick fixes can you apply first when a transfer isn’t adhering?

First, verify heat and pressure are correct, ensure the transfer is cured properly, recoat and bake adhesive powder, re-press the garment, and perform a test on a scrap piece to confirm adhesion before continuing.

What routine checks form a preventive maintenance plan within DTF troubleshooting to minimize DTF transfer issues?

Create a maintenance calendar with nozzle checks and periodic printhead cleaning, quarterly calibration of heat presses and platen pressure, and regular inventory reviews of film, powder, and ink. Maintain a job log and standard operating procedures to reduce recurring transfer issues.

| Aspect | Key Points |

|---|---|

| 1. Common DTF issues and quick fixes | – Transfer not adhering or lifting after curing: causes include insufficient heat/pressure, improper curing, weak adhesive; quick fixes: raise prepress time/temperature by 5–10 seconds, check platen pressure, re-check powder coat and fresh adhesive, inspect film for wrinkles/dust and retouch as needed. |

| – Colors washing out after wash: causes ink saturation too low, incorrect curing, or over-softening; fixes: verify color profiles, avoid over-drying, use proper pre-treat, ensure dense white underbase if used, reapply powder and re-cure with controlled heat. | |

| – White underbase not showing/dull: causes poor powder adhesion or too much heat; fixes: check powder layer, bake longer at correct temp, verify transfer temp/pressure match film specs. | |

| – Ghosting/misalignment/color shifting: causes alignment issues or film slippage; fixes: re-check alignment marks, pre-press garment flat, calibrate heat press, secure transfer with silicone sheet. | |

| – Powder not transferring or excessive powder: causes improper fusion or off heat/pressure window; fixes: re-apply light even coat, bake per guidelines, test on scrap first. | |

| – Cracking/peeling after washing: causes poor adhesion or harsh wash; fixes: ensure spec heat/press, follow garment wash instructions, consider stronger adhesive or longer cure. | |

| – Bleeding/halos around design: causes excess ink or misalignment; fixes: adjust color density, crisp edges, verify film remains aligned. | |

| – Wrinkles/creases in film during transfer: causes non-flat film or uneven heat/pressure; fixes: lay film flat, repress garment, ensure even pressure within recommended range. | |

| – Printer head clogs/ink issues: causes dry ink/nozzle clogs; fixes: routine maintenance, use cleaning cycles, ensure fresh ink and correct profiles to minimize printhead stress. | |

| – Drying/curing/heat settings not matching material: causes wrong heat/dwell time; fixes: follow film/ink guidelines, run tests on similar fabrics. |